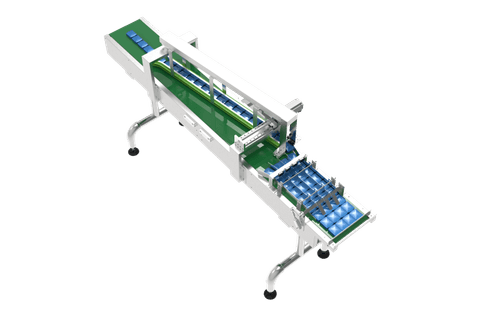

Single-to-Multi Lane Conveyor Diverter System

Single-to-Multi Lane Conveyor Diverter System

Product Introduction

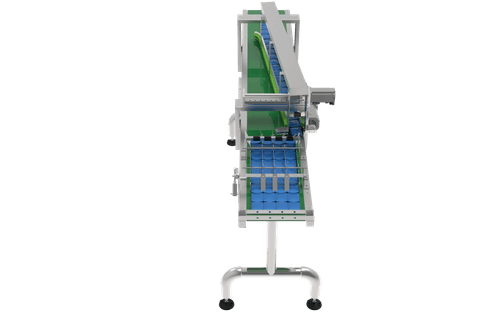

The system dynamically distributes products from a single infeed conveyor to multiple outfeed lanes based on programmable rules. Powered by a high-precision servo-driven diverter module, the system features automatic clamping, accurate optical detection, and user-friendly touchscreen control.

Key Features

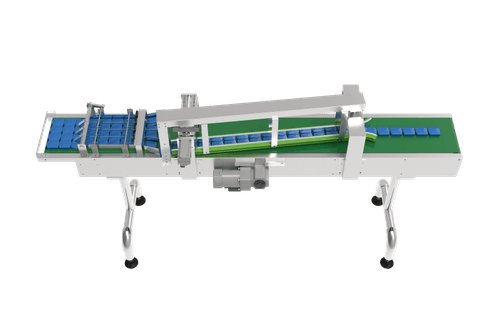

1. Single-Lane Powered Infeed Conveyor

Smooth and consistent transfer of items such as round bottles, square bottles, or cartons.

2. High-Precision Optical Sensor at Infeed

Detects the arrival of products

Triggers positioning and system response

Ensures real-time lane-switching accuracy

3. Servo-Driven Diverter Mechanism

Composed of a ballscrew linear actuator with swing-arm mechanism

Switching time ≤ 0.5 seconds

Process:

Product enters diverter zone

Pneumatic clamp locks product in place to eliminate inertia

Servo module receives PLC instruction

Slide moves product precisely into assigned lane (left/right/multi-lane)

4. Clamping and Positioning Unit

Positioned at diverter output zone

Pneumatically driven clamp engages upon product arrival

Prevents misalignment during servo movement

Ensures stable, repeatable product orientation

5. Anti-Interference Optical Counting Sensors

Supports counting speed ≥ 120 items/min

Dual-layer counting structure:

Inlet sensor: Triggers total count and clamping

Per-lane exit sensors: Independent post-diversion count tracking

| Function | Description |

| Count-Based Splitting | E.g., 3 products to left → 5 to right → loop |

| Time-Based Splitting | Automatically switch lanes at fixed intervals |

| External Signal Trigger | Compatible with robotic arms or barcode scanners |

| Realtime Monitoring | Channel counts, servo status, alarms, logs |

| Secure Access | Tiered password protection for parameter editing |

Applications

- Pharmaceuticals: Bottle and box separation for inspection, labeling, or cartoning

- Food & Beverage: Sorting bottles or packets into multi-lane fillers

- Cosmetics & Chemicals: Adaptive packaging of irregular or fragile containers

- Automation Systems: Upstream sorting for robotic pick-and-place or boxing units

Advantages

- Dynamic lane allocation without manual intervention

- Precise product orientation during transfer

- Adaptable control logic for complex production scenarios

- High-speed and high-accuracy performance

- Modular integration into existing packaging lines

We provide turnkey conveyor sorting systems tailored to your bottle type, speed requirement, and downstream equipment. Integration support available for cartoners and vision systems.