Dual-Row Bottle Cartoning System

Product Introduction

Product Introduction

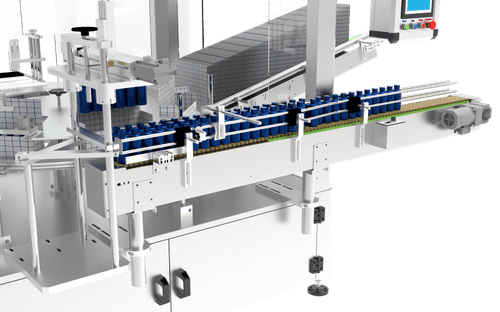

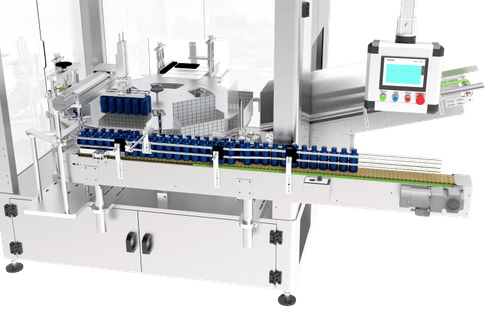

The Single/Double-Row Multi-Bottle Cartoning System is a high-efficiency, flexible automated packaging solution designed for grouping multiple bottles into cartons. Featuring a dual-row分流 (diverging flow) design and side-push cylinders for compact bottle alignment, it ensures precise gripping (±0.1mm positioning) via servo-driven clamping, compatible with round, square, irregular, and fragile bottles (e.g., cosmetics, vials). Supports quick changeover (parameter adjustments or modular tooling swaps) and seamless switching between single/double-row modes, enabling continuous production for high-mix, low-volume demands while maximizing line efficiency.

Core System Functions and Workflow

1. Infeed Integration

Seamlessly connects to the outlets of upstream machines such as filling and labeling systems. Ensures continuous and stable bottle feeding for uninterrupted cartoning.

2. Dual-Row Diverging Structure

A fixed middle divider is installed at the infeed to split a single bottle line into two lanes. This enables efficient dual-row bottle arrangement for higher packing density.

3. Side Push Cylinder Compression

Before the pick-up station, air cylinders push bottles inward from both sides to eliminate gaps. Bottles are realigned into a tight formation, allowing stable and accurate grasping by the robot arm.

4. Intelligent Gripper Mechanism

Driven by servo-powered screw modules, the gripper performs high-precision lateral movements with positioning accuracy up to ±0.1 mm. Equipped with parallel pneumatic jaws, adaptable to various bottle shapes.

Bottle Type Compatibility and Gripper Design

Quick Changeover and Multi-SKU Flexibility

Changeover is easy and fast—only requiring adjustments to robot arm parameters such as spacing and speed, or replacement of the gripping parts. No large-scale mechanical modifications are necessary, supporting short-batch, multi-format production.

Dual and Single Row Compatible

With programmable logic and controlled side-push cylinders, the same system can automatically switch between single-row and dual-row cartoning modes to meet various packaging needs.

Continuous Operation

The system is designed for non-stop bottle feeding, maximizing production efficiency and equipment utilization.

Key Benefits

High-precision positioning (±0.1 mm) via servo-driven modules

Fast and tool-free format changeover

Customizable grippers for irregular or fragile bottles

Seamless integration with upstream and downstream equipment

Applicable across pharmaceutical, cosmetic, food, and chemical industries

Main Technical Data

Machine Details

Touch screen

Advanced Siemens PLC control with touch screen operation function

Turntable

The product will automatically drop into box via star wheel and conveyor.

Open box

Carton feeding system, which realizes the function of adding new carton without stopping the machine.

Station adjusting screw

It can be adjusted according to the size of the box

low air pressure alarm

When the air pressure is unstable, an alarm is given

Circuit board

Advanced electrical control system: the imported encoder is used to control the

electrical centralized, which is convenient to use and simple to operate.

Why Choose LEADTOP

Over 20 years of experience in automated packaging machinery

Modular systems tailored to your unique production flow

Compliance with CE and GMP standards

Global support and long-term service

Integration-ready with robotic cartoners, tray packers, and vision inspection units

Contact Us

Looking to automate and optimize your bottle cartoning process? Reach out for customized solutions tailored to your production line.