What Is a Tablet Counting Machine?

A tablet counting machine is an automated device used to count tablets and capsules accurately. Using advanced optical sensors, it precisely counts and dispenses a predetermined quantity of tablets into bottles or containers. There are two main types of tablet counters: semi-automatic and fully automatic.

Semi automatic tablet counting machines are designed for small to medium-scale production. They require manual bottle placement but offer flexibility and easy changeovers. Automatic tablet counting machines, on the other hand, are built for continuous 24-hour operation in large-scale production environments. They offer high output, high automation, and can be integrated into complete production lines.

1. Tablet Counting Machine Principle

Both semi-automatic and fully automatic tablet counters follow a similar working principle—like a miniature, efficient production line:

- Feeding: Tablets are evenly distributed through a vibrating hopper or tray.

- Detection: Optical sensors (the machine’s “eyes”) detect and count tablets as they pass through the counting channels.

- Counting: The control system records the count in real time with an accuracy of ±0.1% (meaning an error of no more than one tablet per 1,000).

- Filling: The counted tablets are automatically dispensed into waiting bottles.

- Control: All functions are managed via an intuitive touchscreen interface, allowing for real-time monitoring and data recording.

Every process complies with GMP and ISO 15378 standards to ensure accuracy, hygiene, and full regulatory compliance.

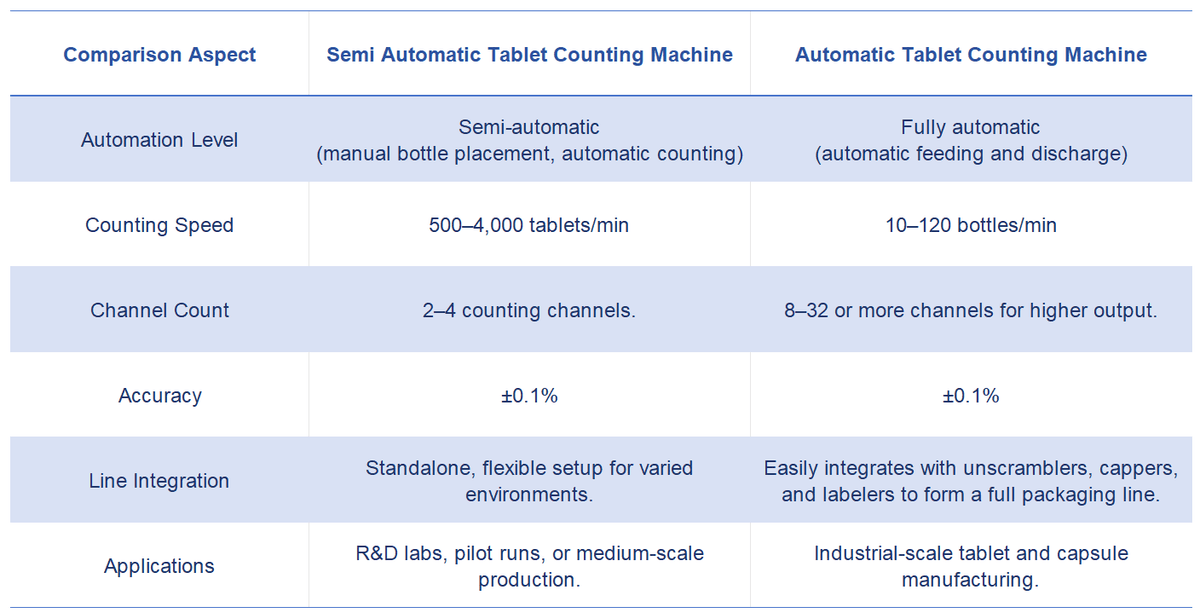

2. Semi Automatic vs. Automatic Tablet Counting Machine

Summary: Both models offer the same excellent accuracy (±0.1%) and hygiene standards—the main differences lie in speed and automation level. Choose based on your production volume and budget.

3. Advantages

- High Accuracy: Optical counting technology ensures extremely low error rates.

- Versatility: Suitable for tablets, hard capsules, softgels, chewing gum, candies, and irregularly shaped products—without damage.

- Hygienic Design: Made of stainless steel with dustproof and anti-static features; fully GMP compliant.

- Easy Operation: Touchscreen control with product recipe storage for quick product changeovers.

4. Applications

Tablet counting machines are widely used in various industries:

- Pharmaceuticals: Counting and bottling of tablets, capsules, and softgels.

- Nutritional Supplements: Vitamins, dietary supplements, and herbal capsules.

- Cosmetics: Capsule-based skincare or beauty beads.

- Food & Chemicals: Granules, gums, or candies requiring precise counting.

How to choose a tablet counting machine?

- Production Capacity: Semi-automatic for small batches; fully automatic for continuous, high-volume production.

- Channel Configuration: Semi-automatic models have 2–4 channels; fully automatic systems have 8–32 channels for faster throughput.

- Counting Speed: Semi-automatic: 500–4,000 tablets/min; Fully automatic: 10–120 bottles/min.

- Product Type: Both types handle tablets, hard capsules, and softgels.

- Compliance: All models meet GMP, CE, and ISO 15378 standards and support 21 CFR Part 11 for data integrity.

Related Questions and Answers

Q1: How can a tablet counting machine achieve ±0.1% accuracy? What if it miscounts?

A1: The machine uses advanced optical sensors and intelligent control logic to detect each passing tablet precisely. Operators can fine-tune vibration frequency and sensor sensitivity based on product type, ensuring optimal accuracy—even for transparent or light-colored products.

Most machines feature an automatic reject system—if a bottle is miscounted, it’s automatically removed from the line. Operators can monitor counts in real time via the touchscreen, and the system will alert them if an error occurs.

Q2: How does the machine count irregularly shaped products?

A2: For irregular tablets, capsules, or candies, the system adapts using:

- Custom vibrating hoppers and channels designed to match product size and shape.

- Adjustable sensor sensitivity for precise detection across various product types.

- Gentle handling mechanisms to prevent chipping or coating damage.

Q3: Can one tablet counting machine handle multiple product types? Is changeover complicated?

A3: Yes. Both semi-automatic and fully automatic machines can handle multiple products.

Each machine includes a recipe storage function that saves optimal settings—vibration frequency, channel parameters, and counting speed—for different products. Switching products typically takes just a few minutes by selecting the appropriate recipe from the touchscreen.

Conclusion

Tablet counting machines are an essential part of pharmaceutical and nutraceutical production. Both semi-automatic and fully automatic models use optical counting systems to guarantee precision, efficiency, and GMP compliance.

Looking for the right tablet counting solution for your production needs?

Contact LTPM CHINA to explore our advanced tablet counting systems featuring:

- 8–32 channel fully automatic models

- 1–4 channel semi-automatic options

- 5-year warranty and full GMP compliance

- Custom turnkey packaging line integration

LTPM CHINA — Delivering precision counting solutions for global pharmaceutical manufacturing.