Fine powders are usually light and fluffy—they produce a lot of dust and are prone to moisture absorption and clumping. Because they are too light and loose, it is difficult to control their dosage accurately. To address these issues, we use a granulator to convert powders into granules, making subsequent handling much easier. Whether for tablet compression, capsule filling, or direct use, granulation allows precise dosage control.

1. What Is a Granulator?

A granulator can transform loose or fine powders into solid granules of specific size and density. In simple terms, it helps powders “stick together,” forming slightly larger, manageable granules for further processing. These granules are uniform in size, shape, and moisture content, making them easier to handle, compress, dry, and package. The process of forming these granules is called granulation, and the equipment used is called a granulator.

Granulators can process powdery raw materials (such as lactose, starch, or active pharmaceutical ingredients), wet or dry materials, heat-sensitive or moisture-sensitive powders. Different raw materials require different granulation methods and equipment.

2. Why Is Granulation Necessary?

Powders tend to segregate, absorb moisture, and form lumps. Granulation can address these issues by increasing particle size and modifying surface properties.

(1) Improve Flowability

Powders may stick to the machine walls, causing intermittent flow during feeding. After granulation, particles flow smoothly like sand, ensuring consistent weight for each tablet or sachet.

(2) Enhance Compressibility

Materials need to compress well for tablet production. Granules compress more evenly than fine powders, reducing the risk of capping, lamination, or weight variation during tablet manufacturing.

(3) Reduce Dust and Segregation

Granules are more stable and less likely to become airborne. This not only improves operator safety but also prevents active ingredients from separating from excipients.

(4) Ensure Uniform Dosage

Granulation ensures that each granule contains the same ratio of active ingredients and excipients, guaranteeing that every tablet has a consistent therapeutic effect. This is a regulatory requirement by agencies like the FDA.

(5) Improve Appearance and Stability

Granulation enhances product appearance (uniform color and texture), increases moisture stability, extends shelf life, and improves dissolution rates.

3. Working Principle of a Granulator

Although granulator designs vary, most follow these four steps:

- Mixing: Raw powder is evenly mixed.

- Granulation:

- Wet granulation: Powders are moistened with a binder to form wet granules.

- Dry granulation: Powders are compacted and then broken into granules.

- Drying: For wet granulation, moisture is removed to harden the granules.

- Sizing: Granules pass through a sieve to achieve uniform particle size.

Dry granulation process:

This method does not use water. Powders are pressed into a compact ribbon by two rollers and then broken into granules.

- Advantages: No drying step; suitable for moisture- or heat-sensitive materials (e.g., Vitamin C, effervescent tablets); energy-efficient.

- Disadvantages: Particle uniformity and roundness may be slightly lower; improper pressure may cause fines or cracks.

4. Types of Granulators

(1) Wet Granulator (High-Shear Granulator)

A high-speed impeller and chopper quickly mix powders with a binder solution to form wet granules. High shear ensures uniform particle size and density.

Best for: Tablets, nutritional granules, instant powders.

Advantages:

- Fast granulation (3–10 minutes per batch)

- Uniform particle size

- Easy to clean and automate

(2) Dry Granulator (Roller Compactor)

Two counter-rotating rollers compress powder into ribbons, which are then milled into granules.

Best for: Moisture- or heat-sensitive powders (e.g., effervescent tablets, certain vitamins).

Advantages:

- No binder or drying needed

- Consistent granule hardness

- Suitable for industrial-scale production

(3) Fluid Bed Granulator (FBG)

Warm air from the bottom fluidizes the powder, and binder solution is sprayed from above. Granules form, grow, and dry simultaneously while suspended.

Best for: Heat-sensitive materials, large-scale continuous production.

Advantages:

- Combines drying and granulation in one unit

- Energy-efficient

- Produces lightweight, porous granules

(4) Vibrating/Oscillating Granulator

A vibrating arm pushes wet material through a screen to form granules, commonly used in R&D or small-scale production.

Best for: Laboratory and pilot-scale production.

Advantages:

- Simple operation

- Suitable for various materials

- Compact design

(5) Plastic Granulator (Recycling)

Not related to pharmaceuticals. Plastic granulators cut, melt, and cool waste plastic into reusable pellets. Technically, this is “pelletizing” rather than pharmaceutical granulation.

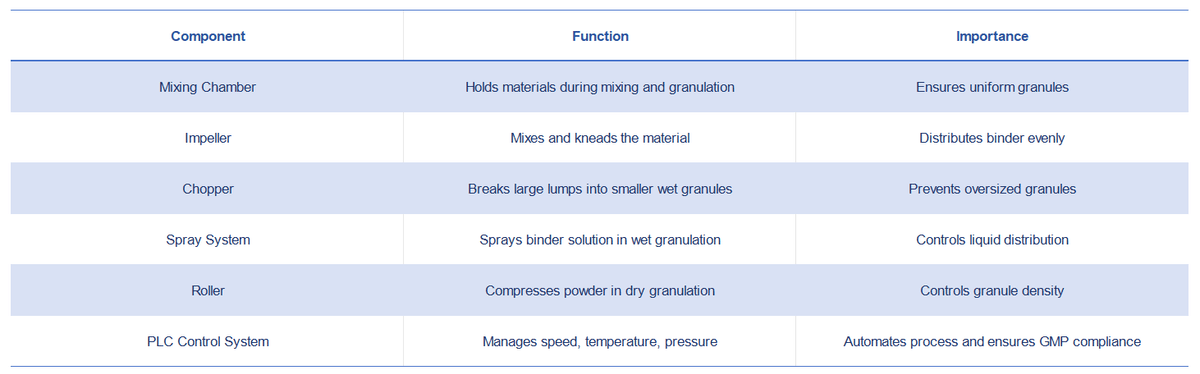

5. Key Components of a Granulator

6. Industrial Applications

Pharmaceuticals:

Granulators are essential for tablet and capsule production. Lactose or MCC mixed with API forms compressible granules. Antibiotics typically use wet granulation, while moisture-sensitive drugs like aspirin use dry granulation.

Food Industry:

Used for instant coffee, tea powders, milk powder, seasonings, spices, and protein powders. Granulation improves solubility, prevents clumping, and increases packaging efficiency.

Chemicals and Fertilizers:

Used for urea, NPK fertilizers, detergents, pigments, and catalysts. Granules require specific mechanical strength and solubility.

Cosmetics and Nutraceuticals:

Granulation prevents dust, improves appearance, and enhances consumer safety for powders like collagen, vitamins, and herbal extracts.

7. Advantages of Using a Granulator

- Uniform particle size and density for smooth downstream processing

- Improved flowability and compressibility for feeding and tableting

- Reduced dust, cleaner environment, and lower product loss

- Enhanced solubility, stability, and product performance

- Higher process efficiency; modern granulators reduce mixing time by 50–70%

- GMP and FDA compliant; simple design, easy maintenance, full process traceability

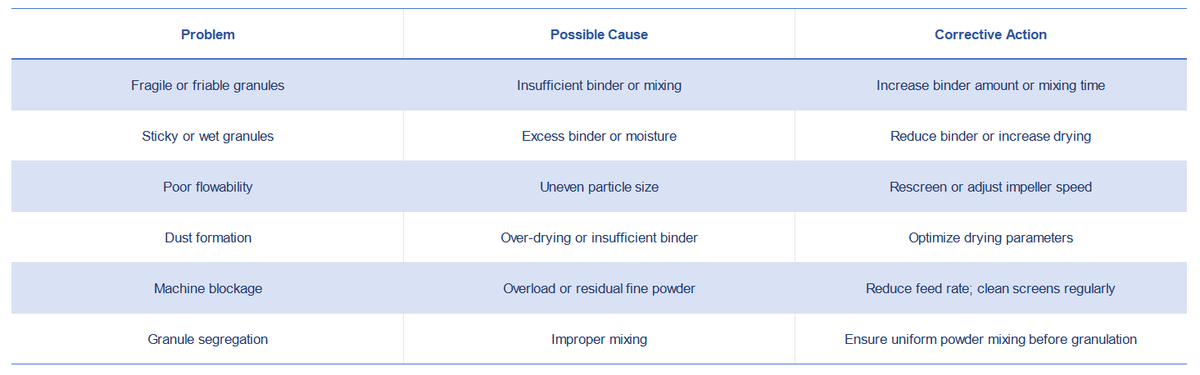

8. Common Problems and Solutions

9. How to Choose the Right Granulator

Choosing the ideal granulator depends on several factors:

- Material Properties: Heat- or moisture-sensitive? Hard or porous granules?

- Production Scale:

- Laboratory: small oscillating granulator

- Pilot scale: wet granulator or small fluid bed granulator

- Industrial scale: dry granulator or fluid bed granulator

- Regulatory and Design Considerations: GMP compliance, easy cleaning and validation, traceable data recording

- Budget and Maintenance: Not only initial cost, but operational cost, spare parts availability, and manufacturer support

10. Conclusion

Granulators convert powders into uniform, stable, and free-flowing granules, making them easier to handle, compress, and package. Whether in pharmaceuticals, food, or chemicals, granulation ensures product consistency, efficiency, and regulatory compliance.

The right granulator does more than produce granules—it determines the quality of the entire production line.

If you are looking for professional, customized granulation solutions, LTPM CHINA is your trusted partner in the pharmaceutical and food industries. We specialize in advanced wet granulators, dry granulators, and fluid bed systems, dedicated to providing you with high-quality service and support.