Alu Alu packaging, also known as cold-formed aluminum-aluminum blister packaging, is a type of pharmaceutical blister pack made entirely from aluminum foil. Because both the top and bottom layers are aluminum, it’s referred to as “Alu Alu” packaging. This design completely seals and protects each dose without the use of plastic, offering an exceptional barrier against moisture, light, and oxygen—making it ideal for tablets and capsules that are sensitive to environmental exposure.

Structure and Composition of Alu Alu Packs

The basic structure of an Alu Alu pack includes:

- Top Layer (Lidding Foil): A hard aluminum foil printed with product and batch information.

- Bottom Layer (Forming Foil): Another layer of aluminum that is cold-formed into cavities to hold tablets or capsules.

Because both layers are aluminum, this packaging provides a full-metal seal—hence the name “Alu Alu packaging.”

Advantages of Alu Alu Blister Packaging

Alu Alu packaging is widely used for products requiring maximum protection. Its benefits include:

- Excellent barrier properties: Protects against moisture, light, oxygen, and odor transfer.

- Extended shelf life: Helps maintain product stability and potency over time.

- Tamper-proof protection: Prevents contamination and tampering.

- Premium appearance: Suitable for export markets, especially in Europe and America.

Compared with standard PVC/PVDC blister packs, Alu Alu provides superior protection for high-value products, though it comes at a slightly higher cost.

What Is an Alu Alu Blister Packing Machine?

An Alu Alu blister packing machine is a specialized piece of equipment that automatically performs forming, filling, sealing, and cutting of Alu Alu blisters.

Working Principle:

- Cold Forming: Mechanical pressure shapes the aluminum foil into cavities—no heat required.

- Product Feeding: Tablets or capsules are accurately placed into each formed cavity.

- Sealing: Another layer of aluminum foil (the lidding foil) is sealed over the top.

- Cutting: The sealed sheet is cut into individual blister packs.

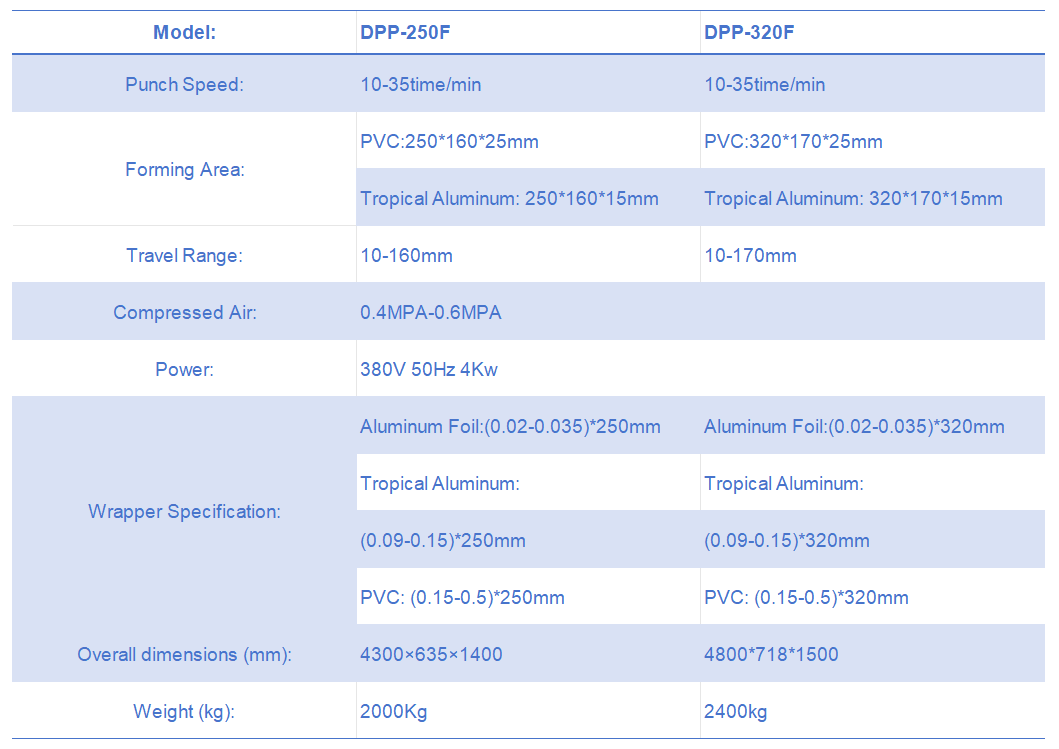

Key Parameters to Consider:

- Forming depth: up to 12 mm

- Maximum foil width: typically 260 mm

- Punching frequency: 15–40 strokes per minute

- Air pressure: 0.6–0.8 MPa

These machines are designed to comply with ISO 15378 (pharmaceutical packaging materials) and GMP standards.

Applications of Alu Alu Packaging

Alu Alu packs are commonly used for:

- Pharmaceutical tablets and capsules, especially moisture- or light-sensitive drugs (e.g., antibiotics)

- Nutritional and dietary supplements

- Herbal products and cosmetics requiring extended shelf life

- Export-grade pharmaceuticals meeting EU and US quality standards

How to Choose the Right Alu Alu Blister Packing Machine

When selecting an Alu Alu blister machine, consider the following:

- Production capacity: Match machine speed and output with your batch size.

- Automation level: Choose between semi-automatic and fully automatic models.

- Format flexibility: Ensure adaptability for different tablet sizes and blister layouts.

- Compliance: Confirm the machine meets GMP, CE, and ISO standards.

- After-sales service: LTPM CHINA offers a 5-year warranty and custom turnkey solutions to meet specific production requirements.

For example, LTPM CHINA’s Alu Alu blister machines are widely used in Europe and America for their high forming accuracy, reliable sealing, and low maintenance costs.

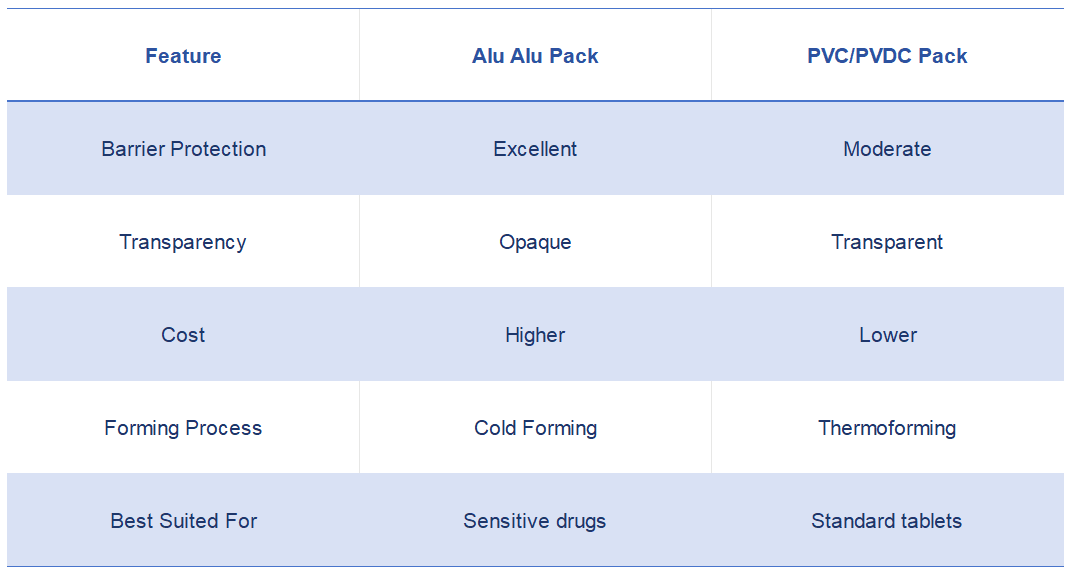

Comparison: Alu Alu Blister vs. PVC Blister Packaging

Conclusion:

If product protection and shelf life are your top priorities, Alu Alu packaging is the clear choice.

Maintenance and Operating Tips

To keep your Alu Alu blister packing machine running at peak performance:

- Clean regularly to prevent cross-contamination.

- Check foil alignment before each production batch.

- Monitor sealing pressure and air settings to ensure consistent sealing quality.

- Lubricate moving parts and follow a preventive maintenance schedule.

Proper maintenance ensures consistent production, extended machine lifespan, and reliable packaging quality.

Summary

Alu Alu packaging is a high-barrier, cold-formed aluminum blister solution ideal for sensitive tablets and capsules. It provides total protection against light, moisture, and gases, extending product stability and shelf life.

By using a reliable Alu Alu blister packing machine—such as those manufactured by LTPM CHINA—pharmaceutical companies can achieve consistent quality, regulatory compliance, and cost-efficient production.

Looking to upgrade your pharmaceutical packaging line?

Explore LTPM CHINA’s Alu Alu Blister Packing Machines — offering 5-year warranty, customized designs, and global after-sales support.

LTPM CHINA — your trusted partner for advanced pharmaceutical packaging solutions.