A single-punch tablet press, also known as an eccentric tablet press or single-station tablet press, is a small tablet press that uses a single set of punches to compress powder into tablets. It can produce tablets

up to 25 mm in diameter and can also produce special shapes upon request . Tablets can be up to 18 mm deep and 8 mm thick . Despite its small size, it can produce up to 5,000 tablets per hour . It is ideal for research, laboratory testing, and small-scale tablet production . It is commonly used in the pharmaceutical, nutraceutical , food , and herbal medicine industries .

Single punch tablet press parts and functions

Die system :

- Up punch : A punch that applies pressure vertically downward from above.

- Lower punch : Located at the bottom, it can move up and down to eject the tablet and control the depth of tablet filling .

- Die ( Cavity ) : A rigid steel ring with a precise hole in the center where the powder is pressed and formed. This determines the shape and size of the tablet.

Hopper : holds the powder or granular material to be compressed.

Cam Track : Guides the punch during compression and ejection of the tablet.

Adjustment system:

- Pressure regulator: Determines the hardness and thickness of the tablet. By adjusting the lowest point of the upper punch, the distance between the upper and lower punches is controlled, thereby controlling the pressure applied to the powder.

- Tablet Weight Regulator: Determines tablet weight. By controlling the position of the lower punch, the volume of powder packed into the die hole is controlled. The lower the lower punch is positioned, the more powder is packed into the die hole, resulting in a heavier tablet.

- Outlet cam : pushes the tablet out of the die cavity after compression.

How Does A Single Punch Tablet Press Work?

1. Filling stage: the punch descends to form a cavity

- The lower punch first descends to its lowest position, creating a cavity of characteristic depth in the fixed die bore .

- The feeder swings over and fills the cavity with powder. The position of the punch determines the volume of powder filled . This is the first step in controlling the tablet weight.

2. Metering stage: Slight rise during downstroke to precisely control weight

- After filling is completed, the lower punch will move upward a small distance to lift the excess powder in the die hole to the upper surface of the middle die.

- The feeder then swings back again, with its bottom acting like a scraper to scrape away excess powder. At this point, the flat surface on the top of the lower punch determines the exact volume of powder remaining in the die hole , ultimately determining the weight of the tablet .

Adjustments during the filling and metering stages ensure that the weight of the filled powder meets the set standards, ensuring the accuracy of the final tablet weight.

3. Compression stage: the upper and lower punches move towards each other, and bidirectional pressure is applied

- The feeder is completely moved out of the way to make room for the tablet press.

- The upper punch begins to descend and enters the middle die hole. At the same time, the lower punch also begins to move upward .

- Both apply pressure to the powder from both above and below, squeezing it into a hard tablet.

This "bidirectional pressure" method is crucial , as it allows the powder particles to expand from the center to both sides, applying force more evenly . This ensures consistent tablet density , improved hardness, and less prone to cracking or delamination .

4. Tablet ejection stage: downward thrust and upward thrust to eject tablets

- After the tableting is completed, the upper punch rises completely and exits the middle die hole.

- The lower punch continues to move upward until its top is flush with the upper surface of the middle die, thereby completely "pushing" the pressed tablet out of the die hole.

- The feeder swings over again, pushing the tablets into the receiving container and simultaneously filling it for the next cycle, starting the process anew.

Key Features and Advantages

- Compact design – takes up little space, perfect for lab use. Single punch tablet press dimensions: 750*400*750mm.

- Easy Operation – user-friendly interface and straightforward controls.

- Low Powder Consumption – suitable for costly active pharmaceutical ingredients (APIs).

- Adjustable Tablet Parameters – control compression force, tablet thickness, and diameter.

- Durable and Reliable – solid mechanical structure with long lifespan.

- Cost-effective – much cheaper than rotary presses , yet produces high output .

- Customizable Options – tooling shapes and sizes can be tailored to client needs.

- 5-Year Warranty – offered by LTPM CHINA, ensuring peace of mind.

Applications of Single Punch Tablet Machines

Single punch tablet presses are simple in structure and easy to operate. They are used by many industries for small batch production and testing. They are commonly found in laboratories, small factories and training centers .

1. Pharmaceutical Industry

Before new drugs are released for large-scale production, they must be tested in small batches. Single -punch tablet presses help test formulations, tablet hardness, and stability without wasting material. They can also be used to prepare customized medications for patients .

2. Nutraceuticals and Supplements

Single- punch tablet presses are widely used in the production of vitamin tablets, herbal tablets, and dietary supplements . Many small and medium-sized companies prefer them because they are affordable and offer flexibility. They can easily test different tablet shapes, sizes, and hardness levels before going into full-scale production.

3. Food Industry

It is commonly used to make candy tablets, mints, and flavored chewable tablets . Single-shot presses ensure uniform shape and size for each product. Smaller candy brands use them for limited runs or specialty products , and some also use them to produce sweetener tablets that dissolve quickly in beverages.

4. Chemical Industry

Single- punch tablet presses are used to produce pesticide , detergent, and catalyst tablets. Due to the unique nature of these raw materials, the machine requires strong corrosion resistance and durability. Automated equipment offers greater efficiency than manual operation.

5. Educational and Research Institutes

Many schools and laboratories purchase a single punch tablet press for training purposes. Students use it to learn the tableting process. Researchers use it to test new ingredients and formulations.

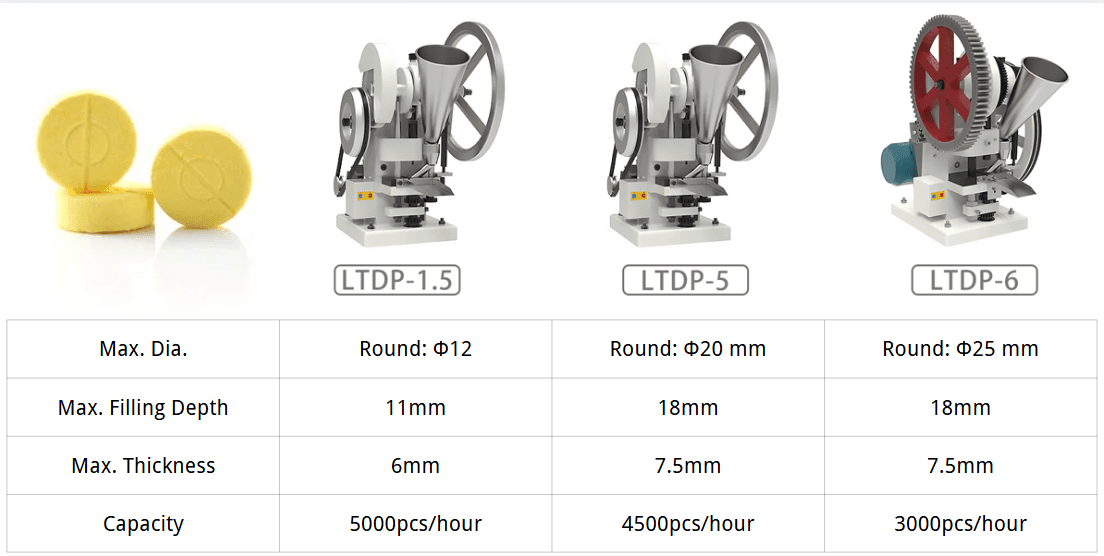

Single Punch Machines Available from LTPM CHINA

These specifications make the single punch press ideal for laboratory use and small-scale production.

Related Questions and Answers

Q1: How to adjust the tablet weight of a single punch tablet press?

A: Tablet weight is primarily controlled by adjusting the depth of the lower punch in the die hole . Rotating the lower punch 's adjustment screw (or handle) changes the depth of the lower punch in the die hole . This change in depth also changes the volume of material that can be accommodated in the die hole , thereby controlling tablet weight .

How to do it :

- Increase tablet weight : Turn the lower punch adjustment screw clockwise to lower the lower punch and increase the filling depth.

- Reduce tablet weight : Turn the lower punch adjustment screw counterclockwise to raise the lower punch and reduce the filling depth.

Important : After adjusting tablet weight, you must readjust the pressure (hardness) setting . This is because the change in fill depth changes the endpoint of the upper punch during compression . The previously set pressure may no longer be suitable. Failure to adjust the pressure setting may result in a change in hardness or problems such as chipping and capping.

Q2: What should I do if "sticking" or "die pulling" occurs during tableting?

A: Punch sticking occurs when tablet material adheres to the punch surface, resulting in uneven or defective tablets. Stop the machine immediately and inspect and clean the punches . Inspect the upper and lower punches for nicks, rust, or material sticking to the surface. Clean the punches thoroughly with alcohol or acetone to maintain a high gloss finish.

Check materials and environment :

- Material is too wet : Pellets may not be completely dried or may have absorbed moisture, causing sticking. Re-dry the pellets and control the ambient humidity.

- Insufficient or uneven lubricant : Add appropriate amount of lubricant (such as magnesium stearate) to the formula and ensure thorough mixing.

- Replace or polish the punch : If the punch surface is worn or becomes rough, it needs to be polished or replaced with a new punch.

Q3: What causes "flaking" or "capping" (a layer of the tablet falls off the top) in extruded tablets? How can I solve this problem?

A: This is usually related to pressure adjustment and material properties.

Excessive pressure : This is the most common cause. Excessive pressure creates excessive internal stress in the tablet, causing it to break when ejected. Reduce the pressure (by lowering the punch).

Particle issues :

- Granules are too dry : Granules have poor plasticity and are prone to breaking. It is necessary to add a wetting agent (such as a small amount of alcohol) to the material or adjust the binder ratio during granulation .

- Excessive fine powder or uneven particle size : These will cause excessive air to be filled into the die hole and poor exhaust during compression. It is necessary to reduce fine powder and improve particle size distribution.

Improper tablet ejection adjustment : The lower punch ejection position is set too high, forcing the tablet to rub against the upper edge of the die hole and break. The lower punch ejection position needs to be lowered appropriately so that the tablet can be ejected smoothly.

Q4: Why does the machine make unusual noises or run unsteadily during tableting?

A: This is usually a sign of a mechanical problem or improper operation.

- Foreign matter falls into the die hole : It is necessary to stop the machine immediately, check and remove the hard objects in the die hole, otherwise the punch and die will be seriously damaged.

- Insufficient lubrication : This is manifested by a lack of lubricating oil in the moving parts of the machine (such as guides, bearings, and cams). All oiling points need to be regularly filled with lubricating oil according to the equipment manual.

- The punch is not installed properly or is severely worn : Check whether the punch is fully inserted into the punch hole and locked. Check whether the punch is shaking or bent.

- Pressure overload : If the pressure is adjusted too high and exceeds the normal load of the machine, the motor and transmission mechanism will make a dull overload sound. It is necessary to reduce the pressure appropriately.

Q5: Why is there such a large difference in tablet weight?

A: Weight difference is an indicator that needs to be controlled key for single punch tablet press.

- Poor granule flowability : Granules that are too wet, contain too much fines, or have a poor shape can lead to poor feeding and uneven filling. Solution : Improve granule flowability (e.g., adding a flow aid, improving the granulation process).

- The lower punch is blocked : "Hanging" means the lower punch cannot move up and down flexibly, causing the scraper to push away some of the particles after filling, resulting in insufficient filling. Solution : Clean the lower punch rod and guide hole to ensure smooth movement.

- Improper scraper adjustment : The scraper is installed too high or too low, either failing to scrape away excess particles or obstructing the lower punch from rising or scraping away the filled particles. Solution : Adjust the scraper to maintain an appropriate gap with the turntable working surface so that it can scrape the material smoothly without interfering with the punch.

Key Points : Pressure (hardness), fill depth (weight), and tablet ejection position are the three most critical control mechanisms in a single-punch tablet press , and they are interrelated. Adjusting any one parameter often requires fine-tuning others to achieve optimal tableting results. Sampling and testing are required after each adjustment until quality requirements are met. For more information on common tableting issues, please visit the article - 12 Common Tablet Defects: Causes and Remedies in Pharmaceutical Manufacturing.

Summary

The single punch tablet press is a reliable, compact, and cost-effective solution for pharmaceutical R &D , laboratories, nutraceutical production, and teaching institutions . It is not designed for high-volume manufacturing but excels in flexibility, precision , and low material consumption.

If your goal is formulation testing, small-batch production, or training , this is the machine you need .

Looking for a high-quality single punch tablet press with a 5-year warranty and full customization options ?