Softgel capsules have a smooth texture and an attractive appearance, and they can encapsulate liquids and semi-solids. From everyday vitamins and fish oil to specialized medicines, they are widely used for packaging such contents.

You can think of a softgel capsule as a small, soft pouch made of gelatin. It is formed and sealed in one step, with the liquid, suspension, or semi-solid material enclosed inside.

1. Structure of a Softgel Capsule

Softgel capsules consist of two main parts:

A. Shell

Mainly made of gelatin, plasticizers (such as glycerin or sorbitol), and water.

- Gelatin helps form the capsule shape.

- Plasticizers (like glycerin) keep the shell soft and flexible.

Other possible ingredients include: - Colorants for identification or branding

- Opaque agents (such as titanium dioxide) to protect light-sensitive substances

- Preservatives to extend shelf life

B. Fill Material

The content inside may be:

- Oil-based: such as vitamin D or fish oil (Omega-3)

- Suspensions: small solid particles dispersed evenly in oil

- Emulsions: oil and water mixed using specific techniques

- Pastes or semi-solid formulations: such as highly concentrated extracts

2. Advantages of Softgel Capsules

Compared to tablets or hard capsules, softgels offer multiple unique benefits:

FeatureSoftgelHard Capsule / TabletDosage formLiquid or semi-liquidSolid powders or granulesBioavailabilityHigher (better absorption)LowerSwallowing comfortSmooth and easyHarder in textureLeakage protectionSealedNot fully sealedAesthetic appealCustomizable colors/shapesLimited options

Main Benefits:

- Fast and efficient absorption: Ideal for fat-soluble vitamins and drugs, allowing quicker uptake by the body.

- High stability: The sealed shell works like a “protective shield,” preventing oxidation and moisture.

- Accurate dosage: Each capsule contains a consistent amount, ensuring stable effects.

- Attractive appearance: A visually appealing product enhances consumer trust and brand image.

3. How Softgel Capsules Are Made

Softgel production requires precise coordination between formulation, encapsulation, and drying. The most commonly used equipment is a softgel encapsulation machine.

Step-by-step process:

- Gelatin Preparation: Gelatin, plasticizers, and water are mixed and heated to form a syrup-like gelatin mass.

- Fill Material Preparation: Active ingredients are evenly mixed into the oil or suspension base under controlled conditions.

- Encapsulation: Two soft gelatin ribbons are pressed together by the machine while injecting the fill material, forming and sealing the capsule. They are then cut into individual capsules.

- Drying: Freshly made capsules are moist and soft, so they are transferred to drying equipment to remove excess moisture and become firm and stable.

- Inspection and Sorting: Automated systems check every capsule for weight, sealing quality, and appearance. Defective products are removed.

- Packaging: Qualified capsules are packed in blisters, bottles, or other formats for market distribution.

4. Softgel Production Equipment

High-quality softgel manufacturing relies on advanced and precise machinery.

LTPM CHINA provides turnkey softgel production lines, including:

- Softgel encapsulation machine: forms and seals capsules in one step

- Gelatin melting tank: prepares the gelatin solution

- Mixing tank: blends active ingredients and excipients

- Tumble dryer: quickly removes surface moisture

- Polishing machine: ensures capsules are clean and glossy

- Inspection and sorting conveyor: detects defects automatically

All machines come with a five-year warranty and are fully customizable to meet GMP production standards.

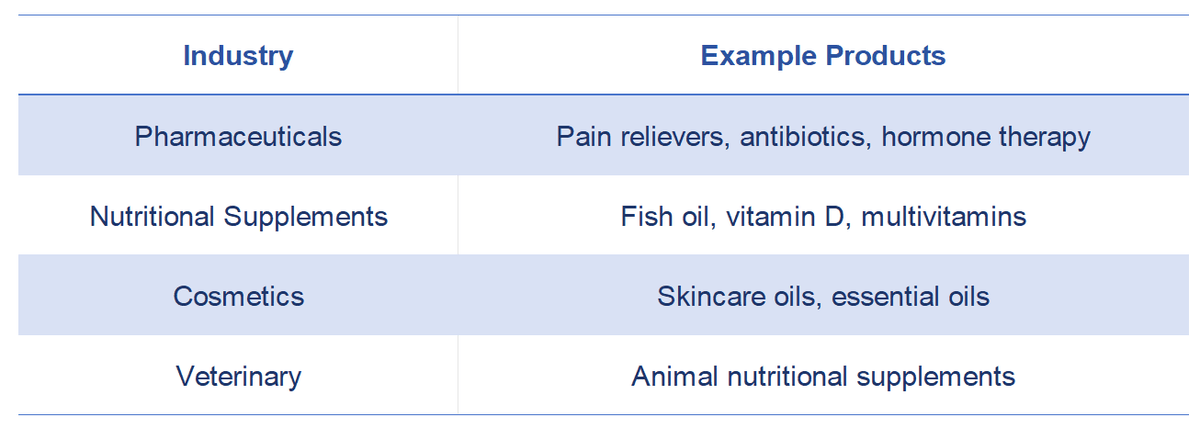

5. Applications of Softgel Capsules

Due to their versatility, softgel capsules are widely used in multiple industries:

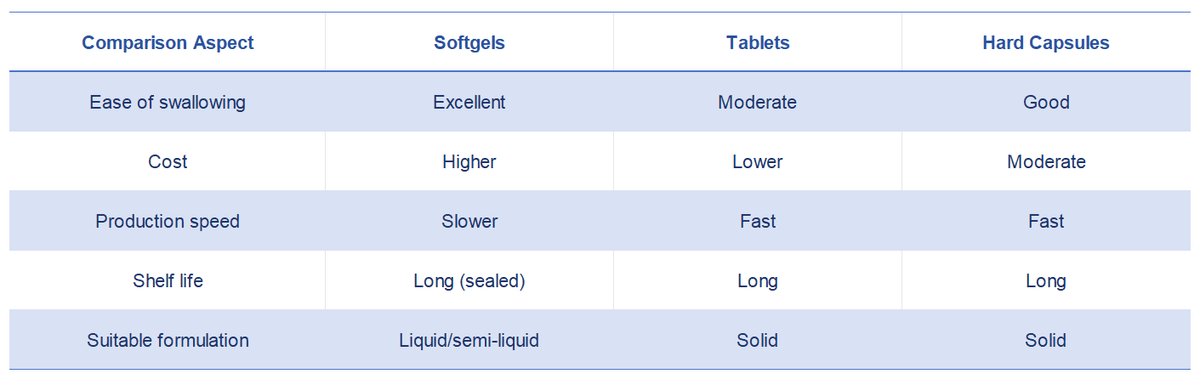

6. Softgel Capsules vs. Other Dosage Forms

Related Questions & Answers

What is the best drying time for softgel capsules?

Usually 16–24 hours, depending on temperature, humidity, and capsule size.

Can softgels contain alcohol or water-based formulations?

It depends. High levels of water or alcohol may affect gelatin stability.

What are the main causes of softgel leakage?

Incorrect sealing temperature, overfilling, or uneven gelatin thickness.

How to extend the shelf life of softgel capsules?

Use antioxidants, maintain low humidity, and ensure sealed packaging.

Can LTPM CHINA provide a turnkey softgel production line?

Yes. LTPM CHINA offers a complete system from gelatin preparation to packaging.

Summary

Softgel capsules combine functionality, aesthetics, and consumer convenience into a powerful dosage form. Their excellent absorption, customizability, and high stability make them essential for pharmaceutical and nutraceutical manufacturers worldwide.

With the advanced equipment from Zhejiang Leadtop Pharmaceutical Machinery Co., Ltd. (LTPM CHINA), manufacturers can achieve efficient, GMP-compliant, and scalable production.

Ready to Start or Expand Your Softgel Production Line?

Contact us to get customizable softgel encapsulation machines with expert technical support and a five-year warranty.