Spray drying is a widely used technology in the pharmaceutical, food, and chemical industries. It converts liquid materials into stable powders in seconds. These liquid materials can be solutions, suspensions, or emulsions . This method is particularly suitable for processing heat-sensitive materials such as active pharmaceutical ingredients, enzymes, probiotics, or milk proteins , as it rapidly evaporates water while maintaining the product's functional properties.

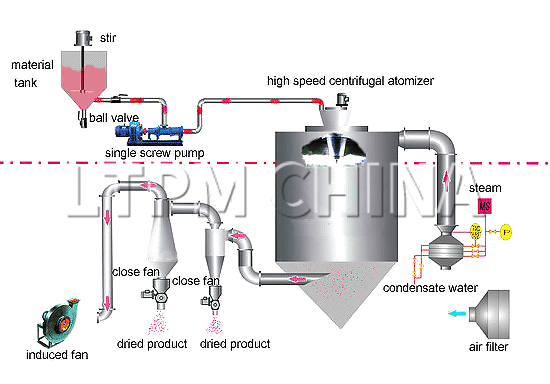

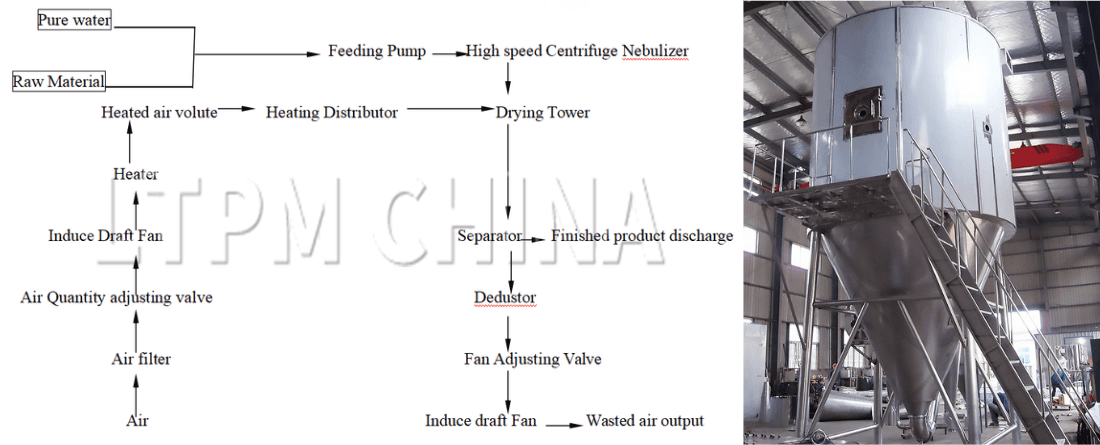

The spray drying process consists of three key steps: atomizing the liquid into tiny droplets; allowing the droplets to fully contact the hot gas , rapidly evaporating the solvent ; and finally, collecting the resulting dry solid particles. The efficiency of these three steps directly determines the particle size, moisture content, and stability of the final product.

How does spray drying work ?

1. Feed preparation

The first step is to prepare the liquid feed . The liquid raw material needs to be blended in advance to ensure stability during the drying process. For example, in pharmaceutical production, to protect the active ingredient , the active ingredient may need to be dissolved or suspended with stabilizers such as sugars or polymers. In the food industry, emulsifiers are added to the liquid raw material to evenly disperse the oil in the water. Furthermore, the viscosity, concentration, and pH of the raw material must be adjusted to create suitable conditions for subsequent atomization .

Note: The liquid must be filtered first to prevent clogging of the nozzle . If it is a suspension or emulsion, it must be stirred evenly to avoid separation of the components.

2. Atomization

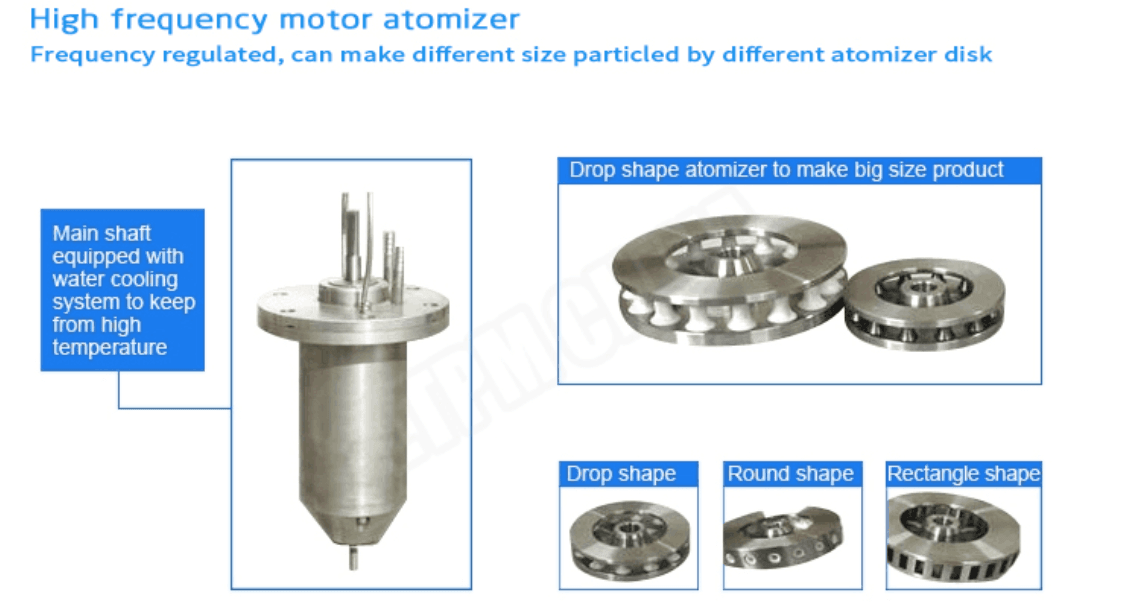

Under high pressure, the liquid passes through a specialized nozzle or atomizer, breaking it into millions of tiny droplets. Droplet size directly influences the drying rate and final particle shape. Common atomization devices include pressure nozzles, two-fluid nozzles, rotating atomizing disks, and ultrasonic atomizers . The choice depends on whether you want an ultrafine, inhalable powder or a larger, free-flowing powder.

Note: During the atomization process, the nozzle or atomizing disk must be kept clean, and the pressure and airflow must be stable to ensure uniform droplet size.

Atomizer Type:

- Pressure Nozzles: Use high liquid pressure to produce a fine spray.

- Two-fluid nozzle: uses compressed gas to atomize the liquid (common in laboratories).

- Rotary Atomizer: A rotating disk used in large-scale production.

- Ultrasonic nebulizer: produces very fine, uniform droplets.

3. Exposure to hot dry gas

The atomized droplets enter the drying chamber and encounter hot gas, causing the water to evaporate rapidly. The hot gas is usually air . If the material is easily oxidized, an inert gas such as nitrogen may also be used . Depending on the direction of the airflow and the movement of the droplets , there are several different airflow patterns:

- Co-directional (air and droplets move in the same direction): gentler and more suitable for heat-sensitive materials.

- Countercurrent (air and liquid droplets flow in opposite directions): The drying efficiency is higher, but the thermal shock to the material is also greater .

- Hybrid flow: combines two principles.

Note: In the drying room, pay attention to whether the material sticks to the wall . This usually indicates that the air flow distribution is unreasonable or there is a problem with the properties of the raw materials, which needs to be adjusted.

4. Droplet drying stage

Each droplet dries in two stages:

Constant speed stage : Water on the droplet surface evaporates rapidly and the droplet gradually shrinks .

Deceleration stage : A solid shell forms on the surface of the droplet, and the internal water must diffuse outward through this shell.

5. Particle Formation

After complete drying, the droplets become solid particles. The final particles may be dense solid particles, or hollow, porous, or even fragile . The final properties (size, shape, density) depend on the material formulation and drying conditions. For example:

- Low solids concentration → hollow, fragile particles

- High viscosity feed → dense, irregular particles

- Fast drying → porous powder with large surface area

6. Powder separation and collection

The dry particles must be separated from the drying gas. The following methods are usually used:

- Cyclone separator : The rotating air flow pushes the particles toward the chamber walls where they are collected .

- Bag filter : Fine particles are trapped on the filter surface .

Large particles generally settle naturally to the bottom of the drying chamber, while fine particles are carried by the air flow to a collection device. Some very fine particles can be recirculated to increase production.

7. Powder packaging

Finally, collect the powder into a container. Depending on the product, you can use the following methods:

- For pharmaceutical products, powders must be protected from moisture and stored under controlled humidity to prevent moisture absorption.

- For food ingredients, powders can be sieved or blended before packaging.

- For sensitive materials, use inert gas packaging to avoid oxidation.

Key parameters affecting spray drying performance

To ensure high powder quality, several key parameters must be carefully adjusted:

Inlet temperature: The inlet temperature must be high enough to ensure rapid evaporation of the raw materials , but not too high to destroy the active ingredients of the raw materials .

Outlet temperature: The outlet temperature can reflect the moisture content of the final product and needs to be strictly controlled .

Feed solid concentration:

- Too high concentration → easily clogs the nozzle and causes uneven powder .

- Too low concentration → may produce hollow particles.

Droplet size:

- If it is too small, it will dry quickly but produce more fine powder.

- if it is too large, it may not dry thoroughly.

Air flow velocity and humidity:

will affect drying efficiency and powder viscosity , and require reasonable design .

Advantages of spray drying

- Produces uniform, reproducible powder.

- Scalable from laboratory to industrial level.

- Optimized for use with heat-sensitive compounds.

- Encapsulation of flavorings, vitamins or biologicals is permitted.

Limitations of spray drying

- High energy consumption.

- Not suitable for processing materials that are particularly sticky or prone to agglomeration .

- The equipment investment is large .

Industrial applications

Pharmaceutical industry: amorphous solid dispersions used to improve drug solubility, inhalation powders, and preparations to protect proteins or enzymes.

Food industry: Common products include milk powder, instant coffee, microcapsulated flavors, probiotic products, etc.

Chemicals and cosmetics: such as detergents, ceramic powders, pigments and cosmetic active ingredients.

Summarize

Spray drying is a fast, flexible, and highly controlled drying method that reliably converts liquids into powders . By carefully managing feed characteristics, drying temperature, and collection systems, manufacturers can consistently produce powders with the desired size, stability, and properties.

At LTPM CHINA , we design and manufacture customizable spray dryers and fluidized bed systems for pharmaceutical, food, and chemical applications . We offer a five-year warranty and customized solutions to help companies achieve reliable, large-scale powder production.

Contact us today to discuss how we can optimize your spray drying line for your specific product needs.