Blister packaging is to protect products from environmental factors such as moisture, oxygen, and light. Different packaging materials can provide different display effects. Aluminum-plastic packaging offers a better display effect because the product can be directly observed through the transparent plastic. Although aluminum-aluminum packaging cannot see the product, it provides better protection. These protective properties are called barrier properties , and they directly affect the shelf life and stability of the product.

Types of barrier properties of blister packaging

Barrier properties determine how well a packaging material prevents harmful elements from entering the product. The three most important types of protection are:

- Moisture barrier performance : Measured by the moisture vapor transmission rate (MVTR) . It indicates how much water vapor can penetrate a material over time. If the protection is weak, moisture-sensitive drugs will degrade rapidly.

- Oxygen barrier properties : The oxygen transmission rate (OTR) measures how easily oxygen can penetrate a package. Oxidation can affect the efficacy and safety of drugs.

- Light-blocking/UV protection : Some drugs are light-sensitive and lose their effectiveness when exposed to light. Depending on the specific needs, the packaging material can be transparent, colored, or opaque.

The proper balance of these barriers ensures that the drug remains stable until its intended expiration date.

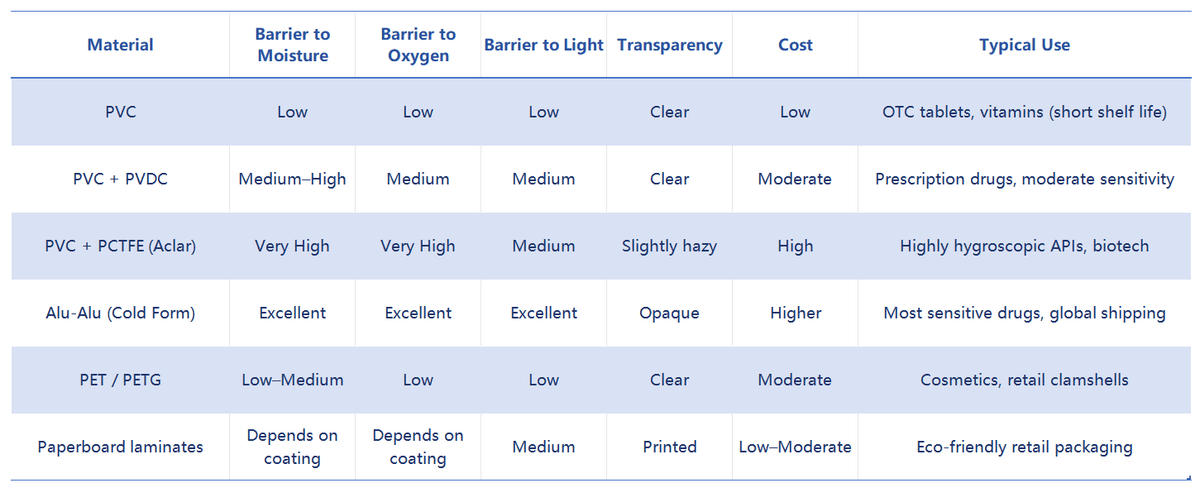

Common blister packaging materials and their barrier levels

Blister packaging materials vary widely in their barrier properties. Standard PVC offers poor barrier properties and is suitable for products with a short shelf life and less sensitive packaging. PVDC or PCTFE-coated films offer enhanced moisture and oxygen barriers and are well-suited for prescription medications. Aluminum cold-formed blisters offer the highest barrier properties but are less transparent and more expensive. The optimal choice depends on the sensitivity of the product, the desired shelf life, and distribution conditions.

How to choose the right material

Choosing blister material is a decision-making process that should consider several key factors:

- Assess product sensitivity – Is your drug hygroscopic (easily absorbs water)? Is it light-sensitive? Will it degrade when exposed to oxygen?

- Define the required shelf life – over-the-counter vitamins may only require 6-12 months of stability, while specialty pharmaceuticals may need to remain effective for 2-3 years.

- Match the packaging to the distribution chain – Products shipped to humid, tropical regions require a stronger barrier film than those distributed locally in a controlled environment.

- Balancing cost and performance – Aluminum Aluminum packaging may have a higher initial cost, but they can prevent costly recalls due to drug degradation.

- Meet regulatory requirements – The packaging is part of the official “container-closure system” and must pass stability studies according to ICH, FDA and EMA standards.

By following these steps, manufacturers can mitigate risk and ensure product safety for patients throughout its shelf life. Learn more about blister packaging.

Related topics and answers

Why is PVDC-coated PVC so common in the pharmaceutical field?

Because it offers significantly improved transparency and moisture and oxygen resistance compared to regular PVC, it is economical and suitable for most prescription drugs.

When should I use aluminum-aluminum composite film instead of PVC film?

For pharmaceuticals that are highly sensitive to moisture and light, or when products need to be transported to areas with extreme climates, aluminum-aluminum composite film is the best choice.

What role do stability studies play in selecting packaging materials?

Stability studies (ICH Q1A) simulate real-world storage conditions to confirm that the packaging will protect the product throughout its intended shelf life. Regulators require these studies before a product can be approved.

Are eco-friendly blister materials a viable alternative?

To reduce environmental impact, paper and recyclable PET blister packaging are being developed, but they generally have weaker barrier properties and are best suited for non-pharmaceutical or less sensitive products.

How does the blister machine adapt to different films?

Thermoforming machines are suitable for PVC and PVDC based films, which require heating to form them. Cold forming machines are suitable for aluminum composite films, which do not require heating but are formed by mechanically pressing the aluminum into shape.

Summary

Barrier properties are central to blister packaging design. They determine how effectively drugs are protected from moisture, oxygen, and light, directly impacting drug safety, stability, and compliance with global regulations. For less sensitive products, PVC remains an economical option, while PVDC and PCTFE coatings offer enhanced protection for more delicate products. Aluminum-aluminum composite films offer the highest level of security, but reduce drug visibility and come at a higher cost.

If you're considering which blister material is best for your pharmaceutical or healthcare product, LTPM CHINA can help. We offer professional testing, custom molds, and advanced blister packaging machines compatible with PVC, PVDC, PCTFE, aluminum, and environmentally friendly materials. Contact us today to request a free material sample or inquire about special discounts on turnkey blister packaging projects .