Gelatin capsule filling is a popular and cost-effective method for preparing personalized supplements, herbal and pharmaceutical formulations. Understanding capsule filling ( filling powders, liquids and oils) can help you choose the most suitable capsule filling method, adapt your raw materials to the appropriate filling method and run efficient production.

Powders, liquids, and oils are the most common materials used in capsule filling. If you want to fill materials into hard gelatin capsules, the filling principle is to separate the hard capsule into two parts (capsule body and capsule cap), fill the materials in, and then seal. If you want to fill materials into soft gelatin capsules, you need special equipment to make the rubber skin of the soft gelatin capsule, then fill the materials into it, and then seal it.

Hard gelatin capsules are suitable for powders, liquids, and oily substances; soft gelatin capsules are more suitable for liquids and oily substances.

I will start with the classification of gelatin capsules, filling steps, and equipment selection to give you a deeper understanding of how to fill gelatin capsules.

Simple Directory

1. Types of Gelatin Capsule Filling Materials

2. How to fill powder into empty gelatin capsules

3. How to fill gelatin capsules with liquid

4. How to fill gelatin capsules with oil

5. Equipment recommendation and selection guide

6. Common Mistakes to Avoid

1. Types of gelatin capsule filling materials

There are two main types of capsules, each with different contents:

- Hard gelatin capsule : Two-piece shell suitable for powders, pills or granules.

- Softgels : One-piece, heat-sealed capsules ideal for oils, extracts and semi-liquid formulas.

Hard capsules are used for dry, flowable materials and some liquids with sealing solutions, while soft capsules are used for oils, fat-soluble compounds, and fluid suspensions that require complete encapsulation.

2. How to fill powder into empty gelatin capsules

Manual filling method (small-scale use)

- Ideal for DIY use or early testing:

- Separate the capsule body and capsule cap.

- Use a spoon, spatula, or funnel to fill the body with the powder.

- Lightly compact the powder and add more as needed.

- Keep capsule tightly capped.

Manual tray filling systems (lab or boutique scale)

- Load the capsule bodies into the lower tray and the capsule caps into the upper tray.

- Use a card or spatula to apply the powder.

- Use a tamping tool to compact the powder.

- Refill as needed, then align and press the two trays together to seal.

Suitable for medium-scale production:

- The capsule feeding, separation, powder compacting and capsule closing parts are automated.

- Throughput is up to 30,000 capsules/hour with a dosing accuracy of ±3%.

- Suitable for powders and granules.

step :

- Load the empty capsules into the machine hopper.

- The machine separates the capsule cap from the capsule body .

- The powder hopper utilizes a tamping pin to distribute the powder into the body.

- Reattach the capsule cap to the capsule body.

- The finished capsules are discharged into a collecting tray.

Ideal for high-volume operations:

- Capsules are automatically sorted, filled, closed and ejected.

- Its functions include powder hopper, compacting station, capsule connection and ejection.

- Output: 40,000–120,000 capsules/hour.

step :

- Filling of empty capsules and powder hoppers.

- The capsules are oriented and separated by a machine.

- The powder is compacted and precisely filled into the body.

- Align and press the cap onto the body.

- The final capsules are polished and discharged.

3. How to fill gelatin capsules with liquid

Liquid filling with hard gelatin capsules

- Use hard capsules that are compatible with liquids and have tight-fitting caps or locking rings.

- Fill approximately 80–90% using a dropper, pipette or liquid capsule filling machine.

- Seal with food-safe adhesive or gelatin solution.

- Store in a dry or cool environment to avoid leakage.

step :

- Prepare a clean work space and sterilize all tools.

- Open hard gelatin capsules manually or by machine.

- Use a pipette or dropper to fill the capsule with liquid—up to 80–90% of the way up.

- Lightly moisten the capsule cap rim with gelatin sealing solution.

- Press the cap firmly onto the body.

- Place the capsules on a tray to dry, preferably in a dehydrator or refrigerator for 6-12 hours.

Soft capsule packaging process:

- Prepare the gelatin block and keep it at a precise temperature (~60-70°C).

- The liquid formulation is filled into a metered pump system.

- Use the softgel encapsulation machine to simultaneously form, fill and seal capsules using rotary die technology.

- Use a tumble dryer or a drying tunnel to dry the capsules.

step :

- Gelatin, glycerin and purified water are heated and mixed to form a film material.

- The liquid active ingredient is loaded into the injection system.

- The gelatin strips and liquid filling material are fed into the rotary moulding machine.

- The machine automatically forms and seals each softgel capsule.

- The capsules are moved to a drying drum or drying tunnel to dry for 12-24 hours.

- The final capsules are inspected, polished and packaged.

4. How to fill gelatin capsules with oil

Oil filling with hard gelatin capsules

- Inject oil only when using oil-grade hard gel capsules (some are designed for low-viscosity oils).

- Heat the oil to reduce viscosity, keeping the temperature below 100°F.

- Use a syringe, micro filler or semi-automatic liquid filler.

- Seal using a heat-sensitive gelatin solution or tape seal.

- Store upright to allow for curing and avoid exposure to moisture.

step :

- Open the capsules and prepare the oil-based formula (warm slightly if necessary).

- Use a calibrated syringe to fill the capsule to 80–90% of the capsule volume.

- Apply sealant or use capsule sealant.

- Cover the capsule and place it upright on a non-stick tray.

- Leave it to dry at room temperature or in a low humidity environment for a few hours.

Oil filling with softgels

Oil soft capsule packaging machine:

- Precise metering of oil by piston metering pump

- Use a rotary mold to seal the gelatin tape

- Seal each capsule to prevent leakage

- Softgels need to be cooled and dried for 12-24 hours before packaging

step :

- Prepare gelatin mixture (gelatin, glycerin, and water).

- Maintain correct temperature and viscosity of oil-based fillers.

- Load gelatin and oil into a rotary softgel capsule machine.

- The machine forms, fills and seals each capsule.

- The capsules are dried in a drum dryer and then transferred to a drying tunnel.

- After drying, the capsules are inspected, polished and packaged.

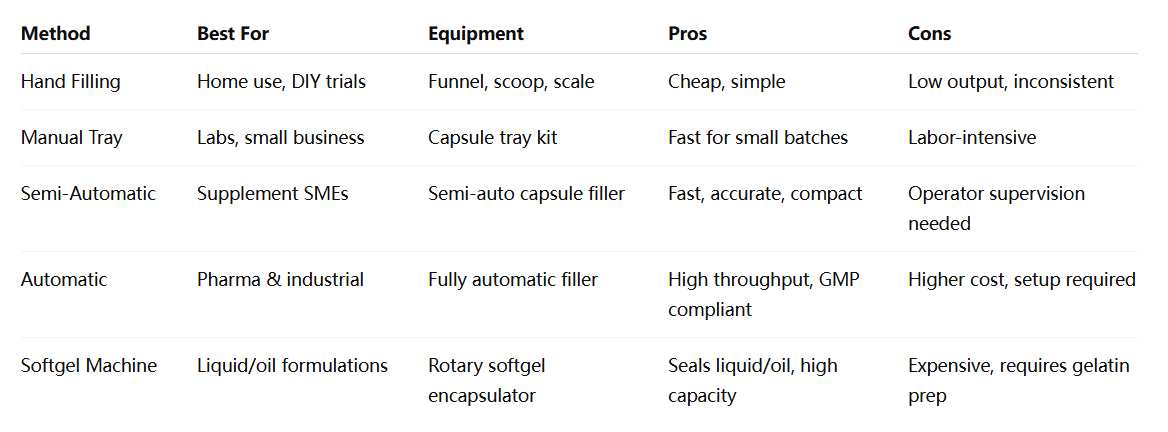

5. Capsule filling machine equipment recommendation and selection guide

6. Common Mistakes

- Using the wrong type of capsule (e.g., standard gelatin for oil-based liquids).

- The capsule is overfilled, causing leakage or rupture.

- Failure to properly seal the hard capsule when using liquids.

- Ignore environmental conditions – Humidity can cause gelatin capsules to soften.

- Skip weight verification – especially for dosage-sensitive formulations.

FAQ

Q1: Can I use hard gelatin capsules to hold liquids or oils?

Only capsules designed for this purpose are suitable. Standard hard capsules are prone to leaking liquids. Use a sealed solution or soft gelatin capsules instead.

Q2: How to choose between hard capsules and soft capsules?

If your formulation is dry, you can choose a hard gelatin capsule. For oily or suspension formulations, soft gelatin capsules offer better sealing, stability, and shelf life.

Q3: What type of machine do I need to fill softgel capsules?

You need a softgel encapsulation machine with a rotary die and drying system. It can complete the forming, filling and sealing of softgels in one go.

Q4: Can I use the same filling equipment to fill powders and liquids?

Not direct filling. Powder filling uses a tamping or screw system. Liquid filling requires pumps, sealing machines and different types of capsules.

Q5: What is the difference between the output of manual machines and automatic machines?

Manual filling speed is 100-400 capsules per hour. Semi-automatic filling machines can fill 10,000-30,000 capsules per hour. Fully automatic production lines and soft gelatin filling machines can fill more than 100,000 capsules per hour.

Whether you are filling powder, liquid or oily products, choosing the right capsule and equipment is crucial. Different materials are suitable for different capsule filling methods. In the production process, it is not only necessary to consider the state of the material and the product of the capsule, but also the capsule size, filling accuracy, equipment quality, etc. If you are a novice and want to learn more about gelatin capsule filling, or you want to upgrade your capsule production line, please feel free to contact us!

We provide complete gelatin capsule filling solutions, all equipment has a five-year warranty and customizable configuration. Five-year warranty is not a commitment that all pharmaceutical machinery manufacturers can give, we will do our utmost to serve you sincerely!

Contact us today for expert consultation, sample testing, and special offers on capsule filling equipment customized to your formulation type.