Fluid bed dryers (FBDs) are widely used in the pharmaceutical, chemical, and food industries for their fast, efficient, and uniform drying performance. However, fluid bed dryers generally cannot handle materials with excessively high moisture content. Materials with moisture levels above 25–30% are typically unsuitable for direct processing in an FBD because the particles become sticky and heavy, preventing proper fluidization and eliminating the drying effect.

However, if most of the moisture is surface moisture, pretreatments such as predrying, granulation, or process modification can make the material suitable for fluid bed drying.

The solutions are clear:

- Dry before entering the FBD: Reduce initial moisture by mechanical dewatering or predrying.

- Shape before entering the FBD: Use top-spray granulation to form stronger wet granules inside the fluid bed before drying.

- Switch technology when necessary: For slurry-like, paste-like, or highly viscous materials, consider vacuum drying, paddle drying, or spray drying instead.

Choosing the proper drying method ultimately requires understanding the material characteristics—especially moisture level and viscosity—and matching them with the right process and equipment.

1. The Inherent Limitations of Fluid Bed Dryers

What counts as “very wet” material?

For fluid bed drying, materials with moisture content above 25–30% are typically considered “very wet.” Moisture can be categorized into:

- Free moisture: Easy to remove; may still be in a liquid state

- Bound moisture: Absorbed within particles; difficult to remove

What qualifies as a high-moisture material?

In the context of fluid bed drying, materials with initial moisture above 25–30% are considered high-moisture or very wet materials. Moisture type matters significantly:

- Free moisture (surface water): Located on the particle surface or between gaps; relatively easy to remove.

- Bound moisture (internal water): Penetrates inside the material or bonds with its structure; requires more energy and time to remove.

High-moisture materials almost always require predrying.

Why Is Wet Material Difficult for an FBD?

Fluidization requires several conditions (supported by research on ScienceDirect and other sources):

- The airflow must be strong enough to lift particles.

- Particles must be non-sticky and easy to separate.

- Particles must have structural strength and flowability.

High-moisture materials break these conditions:

- Greatly increased viscosity: Water acts as a “glue,” causing particles to agglomerate.

- Higher weight: Wet particles are heavier and require stronger airflow to lift.

- Loss of flowability: Wet materials easily clump and block airflow.

Consequently, the bed collapses, the material does not fluidize, and drying cannot occur—this is known as “defluidization” or “bed collapse.”

2. Common Problems When Force-Drying High-Moisture Materials

If standard FBDs are used for high-moisture materials, these issues often occur:

- Severe agglomeration and lump formation

- Uneven fluidization and channeling

- Rapid filter clogging

- Excessively long drying time and high energy consumption

- Inconsistent product quality (uneven moisture, overheating, degradation)

3. Under What Conditions Can an FBD Still Work?

FBDs may still function with relatively wet materials if:

- The material is porous and structurally stable

- Moisture is mostly free water

- Process modifications are applied:

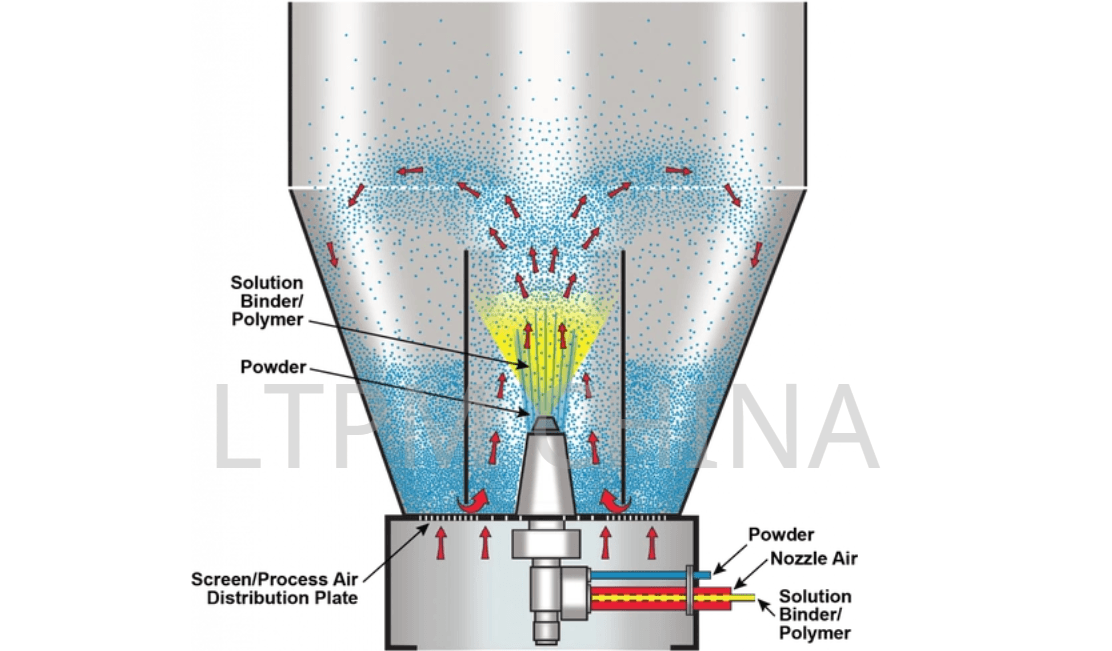

Top-spray granulation + drying:

This is the most effective method. The powder and binder are sprayed and granulated inside the fluid bed, forming stable granules suitable for fluidization, then dried in the same unit.

Optimized operating parameters:

Higher inlet temperature, thinner initial bed layer, or stepwise temperature increase can help the material overcome the most adhesive early phase.

4. Material Types that FBDs Are Clearly Unsuitable For

Consider alternative technologies when dealing with:

- Naturally sticky materials (herbal extracts, high-sugar or high-starch materials)

- Highly hygroscopic fine powders

- Slurry-like or paste-like materials (moisture >50%)

Quick on-site indication:

If material stays still, sticks to the distributor plate, or instantly forms large wet lumps, it is not suitable for FBD drying.

5. Practical Solutions to Make High-Moisture Materials FBD-Friendly

If you still want to use an FBD, consider these adjustments:

A. Pretreatment (Reduce Initial Moisture)

- Mechanical dewatering (centrifuge, filter press)

- Predrying (drum dryer, vacuum belt dryer) to reduce moisture below 25%

B. Change Material Form

- Granulate before drying using top-spray fluid bed granulation

- Add carriers or flow aids to improve fluidity

C. Process & Equipment Optimization

- Improved distributor plate design

- Install agitators or lump breakers

- Use pulsed or variable airflow strategies

6. Alternatives When FBD Is Not Suitable

Studies from organizations like AIChE support selecting drying technology based on material properties.

8. Related Questions

What is minimum fluidization velocity?

It is the minimum airflow required to transition material from a fixed bed to a fluidized bed. Wet materials significantly increase this requirement.

Why don't sticky materials fluidize?

Strong liquid bridge forces and adhesion exceed the airflow’s ability to separate particles.

How to improve fluidization of slightly wet granules?

Add small amounts of dry, free-flowing fines as seeds to absorb surface moisture.

Is granulation mandatory before drying high-moisture powders?

For most powders and fine materials used in foods and pharmaceuticals—yes.

Ideal inlet air temperature for slightly wet materials?

Usually 60–120°C, depending on heat sensitivity. Use lower temperature initially to avoid crusting, then increase later.

Summary

Fluid bed dryers are excellent for powders and granules, but materials with moisture above 25–30% cannot fluidize properly and often cause agglomeration, clogging, and poor efficiency. Predrying, granulation, binders, or optimized parameters can improve performance. For certain materials, alternative technologies are more suitable.

If you need a customizable fluid bed dryer designed for pharmaceutical or industrial applications, LTPM CHINA offers GMP-compliant systems with a 5-year warranty.

Feel free to contact us for tailored drying solutions and equipment quotations based on your material.