Tablet coating, much like giving a pill a “protective jacket,” is a crucial process in pharmaceutical manufacturing. This outer layer improves appearance, enhances stability, and can even control the release of active ingredients. To perform this process efficiently and consistently, professional coating equipment is essential. A high-quality coating machine can precisely control spraying, drying, and other parameters, ensuring every tablet receives a smooth, uniform coating.

The core equipment for tablet coating generally falls into three main categories: the standard coating pan, the perforated drum coating machine, and the fluid bed coater. Each design operates on different principles and is suited to specific production scales, coating types, and budget ranges.

How Does a Tablet Coating Machine Work?

In simple terms, the tablet coating process can be summarized in three main stages:

- Tumbling Motion: Tablets tumble or roll in a pan or drum, ensuring all surfaces are evenly exposed.

- Precision Spraying: The coating solution is atomized and sprayed uniformly onto the tumbling tablets.

- Instant Drying: Simultaneously, filtered and heated air dries the coated tablets, evaporating solvent or moisture and forming a smooth, solid film layer.

Main Types of Tablet Coating Equipment

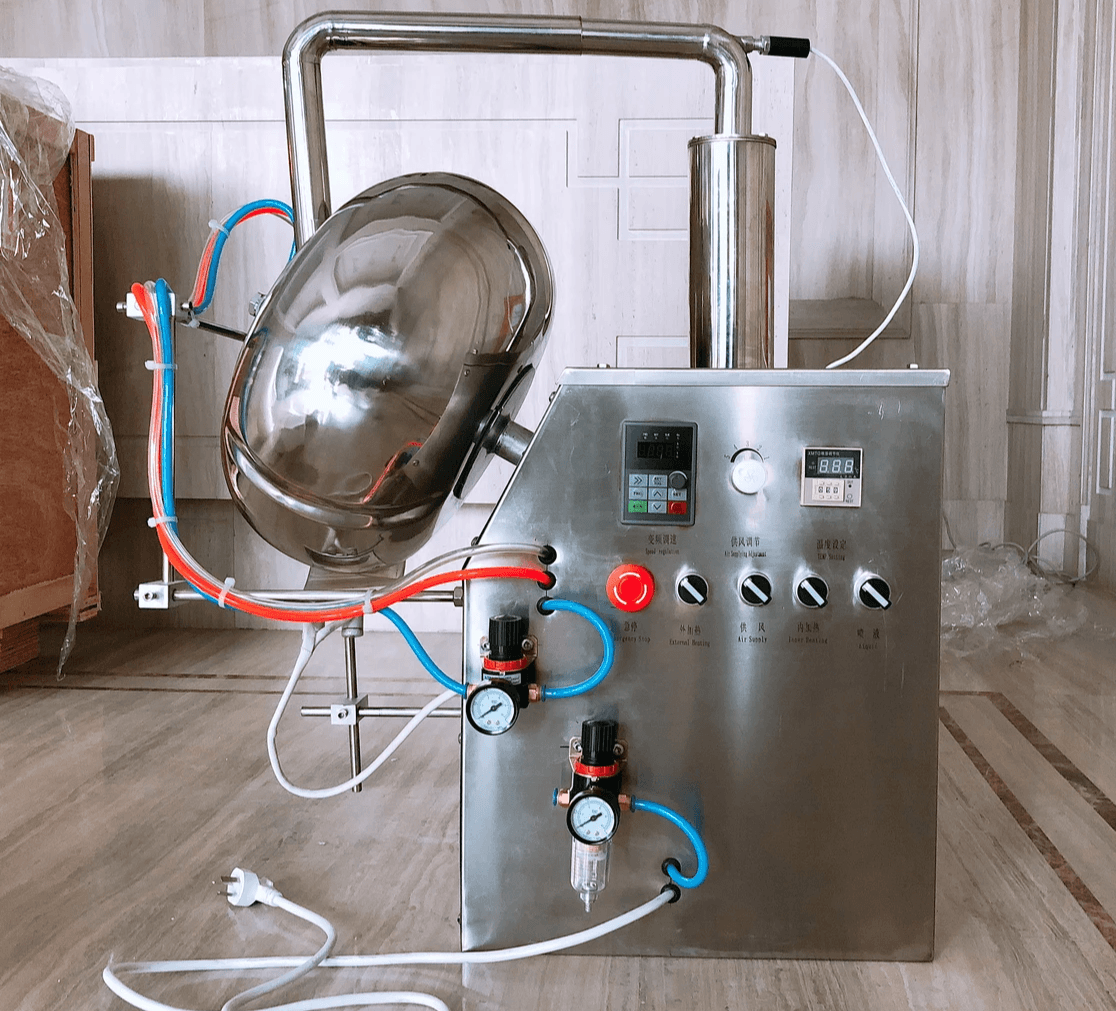

1. Standard Coating Pan

The standard coating pan is the most traditional type of tablet coating equipment. It consists of a circular stainless-steel pan mounted at an angle that rotates to tumble the tablets while the coating liquid is poured or sprayed over them.

Working Principle:

As the pan rotates, the tablets tumble naturally, and the coating liquid is applied to their surface via spray guns or ladles. Heated air assists in drying the coating layer.

Advantages:

- Simple design and low investment cost.

- Easy to operate and maintain.

- Ideal for small-scale or trial production.

Disadvantages:

- Less uniform coating due to inconsistent tablet movement.

- Lower drying efficiency and longer processing time.

- Requires skilled manual operation for optimal results.

Best suited for: Small-batch production, formulation R&D, or nutraceutical and herbal tablets where high coating uniformity is not critical.

2. Perforated Drum Coating Machine (Automatic Coating Machine)

The perforated drum coater, also known as an automatic tablet coating machine, is the industry standard for large-scale pharmaceutical production.

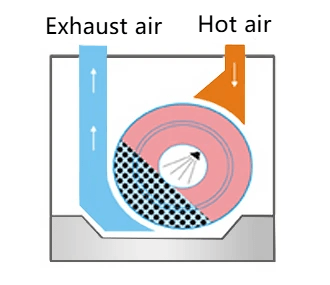

Working Principle:

This system uses a rotating perforated drum in which tablets continuously tumble. Atomized coating solution is sprayed through nozzles located inside the drum, while heated, filtered air passes through the perforations to dry the coating film quickly and evenly.

Advantages:

- Excellent coating uniformity and consistent quality.

- Fast drying and high production efficiency.

- Fully automated control reduces human error and labor costs.

- Energy-efficient and minimizes coating material waste.

Disadvantages:

- Higher initial investment.

- Requires proper calibration and trained operators.

Best suited for: Large-scale production of film-coated, enteric-coated, or controlled-release tablets.

LTPM CHINA’s automatic coating machines feature digital control of spray rate, inlet air temperature, and drum speed—ensuring consistent coating thickness and minimal manual intervention.

3. Fluid Bed Coating Machine

The fluid bed coater is an advanced coating system that utilizes fluidization technology. Tablets or granules are suspended in a stream of heated air while the coating solution is sprayed from the top or bottom, depending on the configuration.

Working Principle:

A powerful air stream flows upward from the bottom of the coating chamber, causing tablets or granules to “float” in a fluidized state—similar to boiling. The coating solution is sprayed onto these suspended particles and immediately dried, forming a uniform film layer.

Advantages:

- Exceptional coating uniformity and high coating efficiency.

- Very fast drying, minimizing risk of sticking or agglomeration.

- Ideal for complex coatings such as controlled-release or enteric coatings.

Disadvantages:

- More complex design and higher technical requirements.

- Precise control of air flow and spray parameters is necessary to prevent sticking.

Best suited for: High-value products, controlled-release or enteric-coated tablets, as well as pellets and microgranules.

How to Choose the Right Coating Equipment

When selecting coating equipment, consider the following factors:

- Production scale: Do you need a lab-scale trial unit or a large-scale production system?

- Automation level: Do you prefer fully automated one-touch operation, or is semi-automatic control acceptable?

- Coating type: Are you producing simple film coatings, or advanced enteric/controlled-release coatings?

- Drying efficiency: Are your products heat-sensitive, or do you require rapid drying cycles?

- Cleaning and batch changeover: Is the equipment easy to clean and suitable for multiple product types?

- Regulatory compliance: Equipment must meet GMP and FDA standards for pharmaceutical manufacturing.

Industry Tip:

Choosing a highly automated system may involve a higher initial investment, but it ensures consistent, high-quality output, reduces human error, and lowers the rejection rate—making it more cost-effective in the long term.

FAQ

What’s the difference between a coating pan and a fluid bed coater?

A coating pan relies on mechanical tumbling, while a fluid bed coater uses air suspension for superior coating uniformity.

Which coating machine is best for film coating?

The perforated drum coating machine is the most widely used and efficient option for film coating applications.

What are common coating defects?

Common issues include blistering, peeling, and color variation—often caused by incorrect drying or spraying settings.

Which coating technology is the most energy-efficient?

Fluid bed coating offers faster drying and overall lower energy consumption.

Summary

Tablet coating machines play a vital role in producing high-quality, uniform, and stable tablets. The three main types—standard coating pans, perforated drum coaters, and fluid bed coaters—each have unique advantages depending on production scale, coating type, and formulation requirements.

At LTPM CHINA, we provide a full range of tablet coating machines, fluid bed systems, and complete solid dosage production lines. All equipment is customizable, GMP-compliant, and comes with a five-year warranty.

Contact us to learn more about our high-performance coating solutions and turnkey pharmaceutical production systems.