Powder mixing is a fundamental operation in the pharmaceutical, food, nutraceutical, and chemical industries. Inhomogeneous mixing can lead to inconsistent product quality, incorrect dosages, unbalanced flavors, and even regulatory non-compliance. Therefore, choosing the right mixing equipment is crucial. Among the many options, V- blenders and ribbon blenders are two of the most commonly used industrial mixers . While they share the same ultimate goal—producing a uniform, homogeneous mixture—they differ significantly in their design, mixing principles, and performance.

V- blenders are ideal for free-flowing, friable powders, providing a gentle, highly uniform mix, while ribbon blenders are better suited for handling large volumes, sticky or agglomerated powders , and requiring faster production cycles.

Basic knowledge of V-type blender and ribbon blender

What is a V-type blender?

V-type blender ( also known as a twin-shell blender ) consists of two tilted cylinders connected at an angle, resembling the letter "V" and rotating about a horizontal axis. As the container rotates, gravity repeatedly mixes and separates the powders, gradually achieving a uniform blend. V-type blenders rely primarily on gravity mixing, without an internal impeller or paddle, resulting in very gentle mixing and are suitable for fine materials and dry powders .

Key Features:

- Gentle mixing: Protects fragile or abrasive-sensitive materials.

- High uniformity: The mixing uniformity is as high as 99%, especially for powders with similar particle size and density.

- Batch Size: Typically small compared to ribbon blenders, but great for precision batches.

Application:

- Active Pharmaceutical Ingredients (API)

- Vitamins and probiotics

- Fine makeup powder

- Delicate food ingredients (e.g., flavorings, herbal extracts)

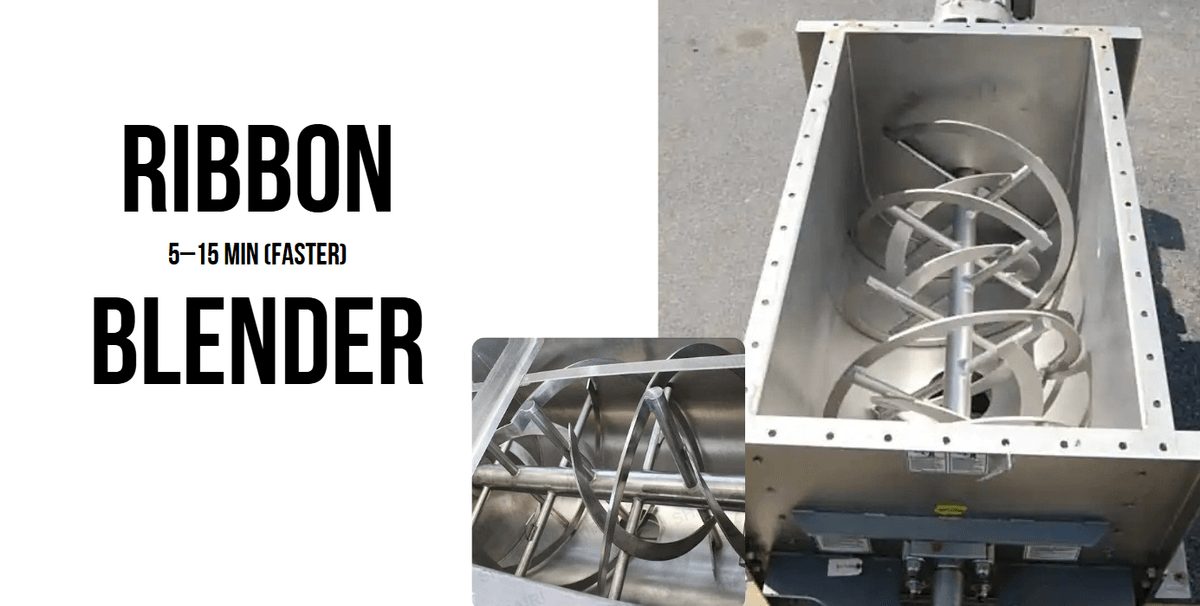

What is a ribbon mixer?

A ribbon mixer features a horizontal, U-shaped trough with inner and outer spiral ribbons mounted on a central axis. These ribbons rotate in opposite directions , generating shear forces that propel the material radially and laterally , creating high-shear convective mixing . Ribbon mixers can process not only free-flowing powders but also sticky, cohesive, or moist materials. They also support the addition of liquids via nozzles, making them suitable for coating or light granulation processes.

Key Features:

- Fast Mix: Typical mixing time is 5-15 minutes.

- Versatility: Can handle free-flowing, cohesive and even slightly sticky powders.

- Liquid addition: nozzles can be installed for coating or granulation.

Application:

- Food powders (protein, flour, spices)

- Nutrient mixture

- Pigments, polymers, detergents

- Large capacity industrial powder

Hybrid performance comparison

1. Cleaning dead corners and cross-contamination risks

Ribbon mixer : The internal structure is complex, with agitator shaft, spiral ribbon, bearing seat, etc. The connection between these components and the cylinder is prone to residual material, making it difficult to clean.

V-type mixer : The V-type mixer is a complete, smooth cavity with no impeller or blades inside . When cleaning, it is just like washing a bottle, and can achieve no dead angle rinsing and wiping .

In the pharmaceutical and high-value-added fine chemical industries, 100% cleaning of equipment is essential every time a product formula is changed . Mixers must be free of residue from previous batches , as this can lead to cross-contamination. This can affect product purity at best, or (in the case of pharmaceuticals) cause serious safety hazards. V-type mixers are the preferred solution to this problem.

2. Destructiveness to particles (shear force)

Ribbon mixer : The material is mixed by forced shearing and extrusion through the spiral ribbon. It will crush crystals and grind particles , and cannot maintain the integrity of the material particles, resulting in:

- Producing too much fine powder affects product fluidity.

- Changes in bulk density and surface area of the material can affect subsequent tableting or filling processes.

- Destroy the coating layer of coated particles.

V-type mixer : relies entirely on gravity for gentle tumbling and dispersing mixing, with almost zero shear force . It can perfectly maintain the integrity of the material .

3. Heat Generation

Ribbon blenders : Mechanical agitation generates heat due to friction with the material. They are not suitable for heat-sensitive materials (such as certain vitamins, probiotics, polymers, or low-melting-point materials) . This temperature rise can cause ingredient degradation, agglomeration, or melting.

V-type mixer : almost no mechanical friction, negligible temperature rise, ideal for processing heat-sensitive materials.

4. Limits of mixing uniformity

Ribbon blender: The mixing uniformity is very good (usually RSD can reach 1%-3%), but its uniformity performance is not as good as that of V-type mixer for the distribution of trace ingredients (such as additives below 0.1%) .

V-type blender: V-type blender achieves uniform mixing through repeated division and merging . It is good at processing low-dose, high-activity ingredients, with a uniformity of over 99.5% (RSD can be less than 1%).

Mixing time

- V blender: 15-30 minutes (depending on powder characteristics).

- Ribbon blender: 5-15 minutes (faster, but more energy).

the absolute king in the following scenarios , while the ribbon mixer is not up to the task .

- Pharmaceutical industry: mixing API and excipients, low-dose drugs, and fragile crystalline drugs. Here, cleanliness, no contamination, and zero particle damage are the primary requirements.

- High-value nutritional products: mixed with trace vitamins, probiotics and other heat-sensitive and fragile ingredients.

- High-end chemicals/electronic materials: Powders that need to maintain specific crystal form and particle size distribution.

- High-variety, small-batch production: because the material change and cleaning are quick and thorough.

How to choo

se a suitable mixing machine?

Choosing between a V- blender and a ribbon blender depends on a variety of factors. If your powder is friable, free-flowing, and requires high precision , a V- blender is ideal. If you have high production volumes, very cohesive powders, or require fast turnarounds , a ribbon blender will be more suitable.

Consider the following checklist:

- Powder properties: good fluidity and strong viscosity.

- Batch size and scale: small batch production versus large batch production.

- Mixing speed requirements: precision and productivity.

- Cleanliness and compliance standards: GMP and general food/chemicals.

- Budget and space availability: dedicated investment versus cost-effective bulk mixing.

Simple and crude judgment method:

Ask yourself: Are my materials likely to be ground? Are my products likely to be contaminated?

If the answer is "afraid" , then choose the V-type blender.

If the answer is "no" , give priority to the ribbon blender.

Related Questions (FAQs)

Can a ribbon mixer handle fragile materials?

Yes, but fragile particles may break due to high shear forces.

What are the pharmaceutical industry's requirements for mixing uniformity?

Generally, the content uniformity is required to be within ±5%RSD (relative standard deviation).

Can these mixers add liquid adhesives?

Yes, the ribbon mixer is suitable for mixing materials that use a nozzle to add liquids , while the V-type mixer is only suitable for mixing dry powders .

How do ribbon blenders compare to double cone blenders?

The tumbling action of a double-cone blender is similar to that of a V-type blender , but V-type blenders generally provide better uniformity. While it possesses the characteristics of a V-type blender, a ribbon blender's advantage lies in its suitability for mixing viscous liquids. Due to its unique V-shaped structure, a V-type blender offers more points for material separation and combination, resulting in slightly higher mixing efficiency than a double-cone blender. However, this requires higher equipment manufacturing and dynamic balancing. The double-cone blender's simpler structure allows for larger capacity. The choice between the two often depends on the specific material and the manufacturer's technical details.

What safety and compliance standards apply?

The machine must comply with GMP, FDA 21 CFR standards and ISO quality management system.

Summary

Both V- blenders and ribbon blenders play a vital role in powder mixing. V- blenders are the gold standard for industries where gentle mixing and high uniformity are paramount, particularly in the pharmaceutical industry. Ribbon blenders , on the other hand , offer faster mixing speeds, larger capacities, and greater versatility, making them a workhorse in the food and chemical industries.

Don’t just assume that “just buy a ribbon blender”, but make your decision based on your “material properties” and “process requirements”:

- If your material is a common powder (such as flour, protein powder, chemical raw materials), even if it is a bit sticky, and you need to produce it quickly and in large quantities, and the requirements for particle breakage and cross contamination are not extreme - then the ribbon mixer is your cost-effective choice.

- If your materials are expensive, fragile, or heat-sensitive (such as pharmaceuticals or high-end additives), or you have extreme requirements for cleanliness and cross-contamination (such as GMP workshops), then the V-type blender is your only choice, and its value far exceeds its price.

LTPM CHINA specializes in manufacturing customized solid dosage equipment, including V-type blenders and ribbon blenders. Our solutions are designed for the global pharmaceutical, nutraceutical, food, and chemical industries. Each unit comes with a five-year warranty, turnkey installation, and full compliance with global GMP standards. Learn more.