Tooling plays a crucial role in the operation of a single punch tablet press. The right tooling ensures that your tablets are produced to the highest quality standards, with the desired shape, weight, and consistency. In this article, we’ll guide you on how to optimize tablet pressing with the right tooling.

Types of Tooling

When selecting tooling for your single punch tablet press, there are several types to consider:

· Punches and Dies: These are the most basic forms of tooling, available in various shapes and sizes. Punches are the parts that apply pressure to the material, while dies contain the material and help shape the tablet.

· Specialty Tooling: Depending on the type of tablet being produced, you may need specialty tooling such as embossing dies for branding or custom designs.

How Tooling Affects Tablet Quality

Tooling is essential for ensuring the quality of your tablets. The type and condition of the punches and dies can affect:

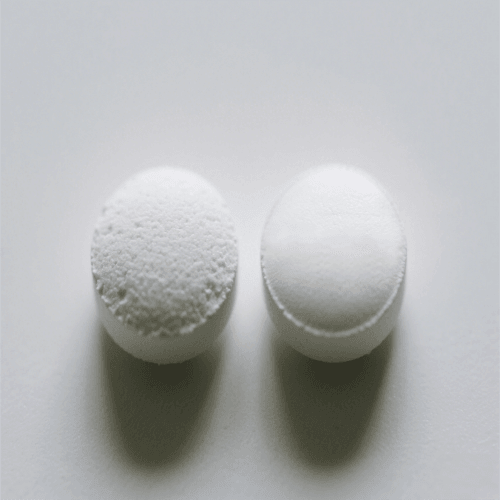

· Tablet Shape: If your tooling is damaged or incorrectly sized, the tablets may come out misshapen or inconsistent.

· Tablet Weight: Worn tooling can lead to inconsistent tablet weight, which can affect dosage accuracy.

· Surface Quality: Worn dies can leave marks on the tablets, which could affect their appearance and consumer perception.

Replacing Tooling

It’s important to know when your tooling needs to be replaced. Signs that your tooling may need replacing include:

· Frequent Tablet Defects: If you start noticing defects like cracks or rough surfaces more frequently, it may be time to replace the tooling.

· Reduced Output: If the output of your machine decreases, this could indicate worn punches and dies that need replacing.

Tooling Maintenance

To extend the lifespan of your tooling and avoid production issues, regular maintenance is crucial. Here’s how you can maintain your punches and dies:

· Clean Regularly: After each production run, thoroughly clean the tooling to remove any powder residue.

· Inspect for Damage: Regularly inspect the punches and dies for signs of wear or damage. Replace any parts that are showing signs of significant wear.

· Lubricate Tooling: Apply a thin layer of lubricant to the punches and dies to reduce friction and prevent damage during operation.

Tooling Adjustments for Different Formulations

When working with different formulations or materials, you may need to adjust the tooling settings to achieve optimal results:

· Granulation Properties: Some powders require finer punches or different die sizes to ensure proper tablet formation.

· Moisture Content: If the material being pressed has high moisture content, you may need to adjust the compression force or use tooling with a different shape to avoid defects like cracking.

Optimizing your single punch tablet press starts with the right tooling. By selecting the appropriate punches and dies, maintaining them regularly, and making adjustments based on the material properties, you can ensure high-quality tablet production with minimal downtime.